How to Make Track and Trace Marking and Coding Work for Your Company

End-to-end product traceability is more important than ever. Track and trace marking and coding ensures supply chain visibility, facilitates smoother supplier and partner relationships, minimizes the impact and scope of product recalls, and bolsters consumer confidence by providing richer information about the products they buy. In this blog we’ll discuss some of the latest trends and innovations in track and trace coding.

What is track and trace coding?

Track and trace coding involves the use of unique data-rich codes to identify items, products, cartons, and pallets as they move through the supply chain from the source to the consumer. Track and trace coding enhances traceability by enabling companies to track the flow of their goods from farms and raw materials suppliers through the manufacturing, packaging, shipping, warehousing, and stocking of items in stores.

Depending on the type of code used, the identifying information stored within it may include the product’s origins, raw materials or ingredients, when it was manufactured, batch number, expiration date, destination, and buyer-focused product information, among other things. In effect, modern track and trace coding tells the story of a product’s origins and its journey all the way to the consumer.

How does track and trace coding work?

Codes – usually in the form of a barcode or 2D code – are assigned as unique identifiers and printed directly on the product packaging and/or on a label that is affixed to the product, package, carton, or pallet. The codes are scanned and read at different points along the supply chain to enable tracking of the product’s location toward its destination and to provide information to supply chain partners along the way.

The track and trace “story” is contained in unique 2D barcodes and managed through track and trace software solutions. Ideally, track and trace software integrates with marking and coding systems to automate code creation and placement. Details about each product’s journey can then be accessed by scanning the 2D code.

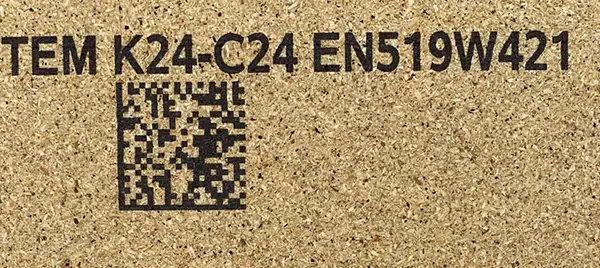

Information rich 2D barcodes such as this on an engineered wood board are at the core of modern track and trace implementations.

Why should you implement track and trace coding?

In many ways, produce and consumer packaged goods (CPG) companies are leading the way in the use of 2D barcodes for track and trace, but in today’s marketplace, manufacturers of all kinds can benefit in important ways:

Improved automation and internal traceability

2D codes, when used with vision systems and machine readers for code verification and validation, provide a greater amount of data on parts and materials as they go through your production process, supporting quality control, sorting, routing, and internal traceability.

Enhanced authentication, anti-counterfeiting and anti-pirating

The depth and quality of information contained in 2D barcodes makes it harder to counterfeit and easier to verify the authenticity of products. Track and trace codes help manufacturers and their trading partners ensure that the materials they use and products they sell are authentic and haven’t been pirated or stolen.

Improved velocity and inventory management

When connected with back-end systems, 2D code readers enable brands and their retail partners to scan, track and trace the locations of their products wherever they are – the loading dock, in transit with the shipper, in the warehouse, or stocked on shelves. That enhanced visibility helps you address bottlenecks and keeps your products moving to their destinations.

Better visibility and recall readiness

2D track and trace codes enhance a manufacturer’s ability to quickly trace and recall only the faulty or corrupted materials and products from anywhere in the supply chain. Facilitating highly targeted, fast recalls reduces liability and demonstrates your brand’s commitment to quality.

Easier regulatory compliance

Traceability is a requirement for many industries, particularly produce, food and beverage, pharmaceuticals and electronics. Track and trace coding with 2D marks helps you ensure you are in compliance with regulations and provides an added measure of traceability that helps ensure the integrity of the supply chain.

Drives brand awareness and customer connection

Because they can carry more detail about products, materials, and origins, 2D codes that can be easily scanned with a smartphone enable deeper connection with partners and customers who are increasingly concerned about the origins of the products they buy. 2D codes enable a brand to tell the story of a product – a valuable asset for marketing, especially for premium products aimed at environmentally and socially conscious consumers.

Build better B2B and B2C connections with GS1 Digital Link

GS1, the standards body for barcodes, is leading the 2D barcode effort to help suppliers, manufacturers, warehousers, shippers and customers connect and take advantage of better, more detailed information about materials and products for “improved inventory management, enhanced recall readiness, greater sustainability and ethical sourcing, better product authentication, and greater brand trust.”

The new GS1 Digital Link standard further extends the power and flexibility of 2D barcodes by enabling connections to all types of business-to-business and business-to-consumer information.

For example, if you put a 2D QR code on your product today, it will likely point to a single, specific website that provides more information about the product. GS1 Digital Link takes that a step further, using the detailed capabilities of 2D codes to carry identifiers that enable manufacturers and brands to link to multiple information sources from one simple 2D code. For a deeper dive, take a look at our Q&A with GS1’s Steven Keddie.

What do I need today to take advantage of track and trace coding?

There are three essential elements that support effective track and trace coding:

-

- Print technology

- Quality ink

- Integration and marking automation

Without high-quality printed codes, machine readers and code scanners are useless. Poorly printed, smeared or otherwise unreadable codes make track and trace coding difficult, if not impossible, and can result in your products being routed to the wrong place, held up in quality holds or sold at the wrong price – all of which hit your bottom line hard.

Printers make it all happen

The quality barcodes required for track and trace coding are made with high-resolution thermal and piezo inkjet printers. Investing in these high-quality printers now ensures you are able to take advantage of the benefits of 2D marks for track and trace coding today, while future-proofing your marking by staying ahead of industry requirements and tomorrow’s coding innovations.

Ink quality matters

A smeared, unreadable code is as good as no code at all. For reliable results you need to make sure you have the right ink for your substrate and application. We explore this is detail in our two-part blog series on selecting ink for marking applications.

Integration and automation

Error-prone manual processes should be avoided when implementing track and track solutions. Accuracy is paramount. Data should flow seamlessly from ERP and track and trace software solutions through to your marking and coding operations. Bar codes should all be scanned and validated at multiple stops, including manufacturing, packaging and palletizing

The good news is, if you invest in a universal print controller such as MPERIA today, you don’t have to upgrade all your printers at once. Because MPERIA works with all types of printers and readers, you can start taking advantage of track and trace coding with 2D marks today – where and when it makes the most sense for your company – while ensuring you’re ready for the next innovation that comes down the pike.

Contact us to learn more about how high-quality printers and automated print controllers can help you make the most of track and trace coding today – and take advantage of tomorrow’s innovations.