Building Materials

Building materials have a broad range of marking needs and requirements. Whatever your product line, with the right inkjet printing technology you’ll get clean, clear reliable marks along with greater speed and efficiency, reduced costs and improved traceability – internally and through the supply chain.

Marking and Coding Solutions for the Building Products Industry

The marking and coding needs of the building products industry are as varied as the materials themselves.

|

|

As an industrial producer, your inks and marking equipment need to work reliably in highly challenging manufacturing environments. Uneven and oddly shaped surfaces, dust, oil, residue, hot and cold temperatures can all dramatically affect print quality.

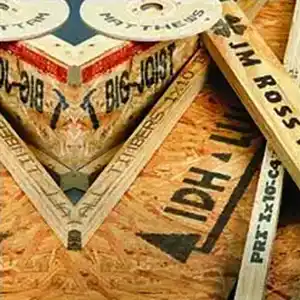

Whether you’re showcasing your brand with big, bold trademarks and certifications or you’re printing tracking information, specs, serial numbers, or barcodes, Matthews offers a line-up of workhorse, drop-on-demand (DOD) valvejet and inkjet printers that give you great flexibility while standing up to the toughest conditions of your manufacturing environment.

Production increases and cost savings add up for truss manufacturer

Boost your production and business results

Choosing the right print technology can make a positive impact on your bottom line. The type of technology you use for marking and coding on building products affects the:

- Speed and efficiency of your marking

- Quality, accuracy and reliability of your marks

- Ink consumption and consumable costs

- Labor required for changeovers

- Amount and interval of maintenance required

- Business and supply chain velocity

You need a marking solution that delivers proven performance and reliability in the toughest of environments and can easily adapt to new requirements as your operation grows and evolves.

No other printing technology offers the clarity, convenience, versatility and cost savings of modern DOD valvejet printers and inkjet printers for primary product marking, barcodes, 2D codes, labeling, bag marking and pallet marking.

Marking technology that meets your unique needs

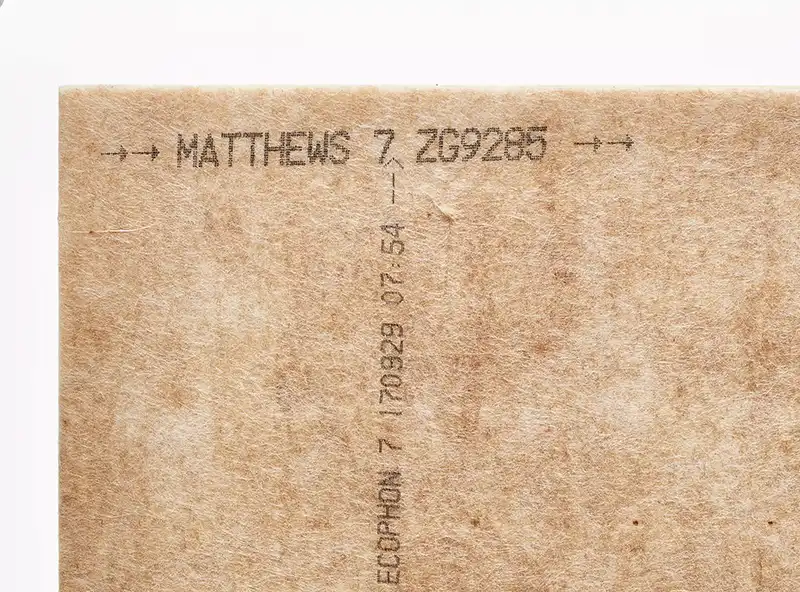

Matthews has a long tradition of offering industrial marking and coding products that are rugged, efficient, and reliable, producing marks of unmatched quality on a wide variety of substrates.

With Matthews inks and printers, you’ll get consistently clean, legible marks and codes on your building products, and you’ll reap the business benefits of greater flexibility, reduced costs, and proven reliability – without the maintenance headaches.

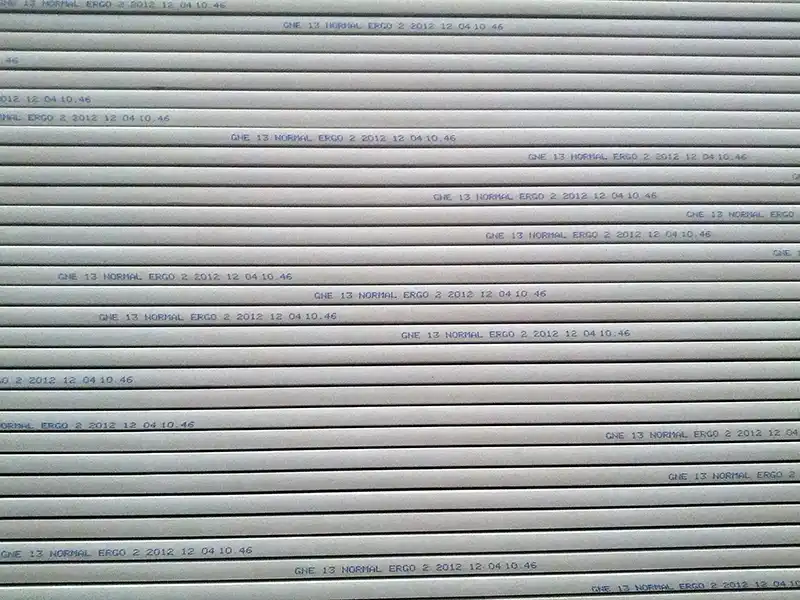

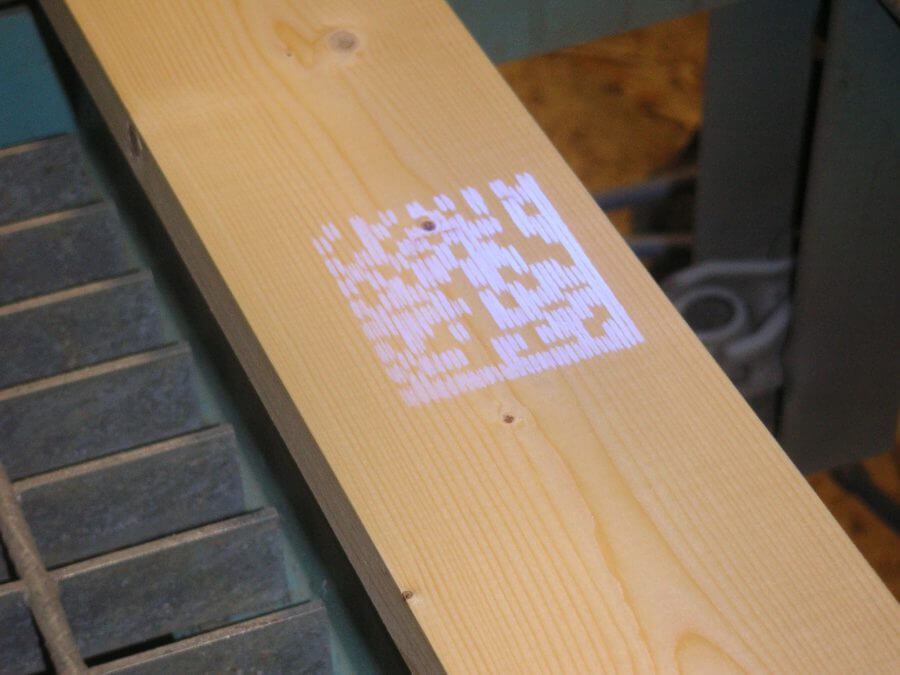

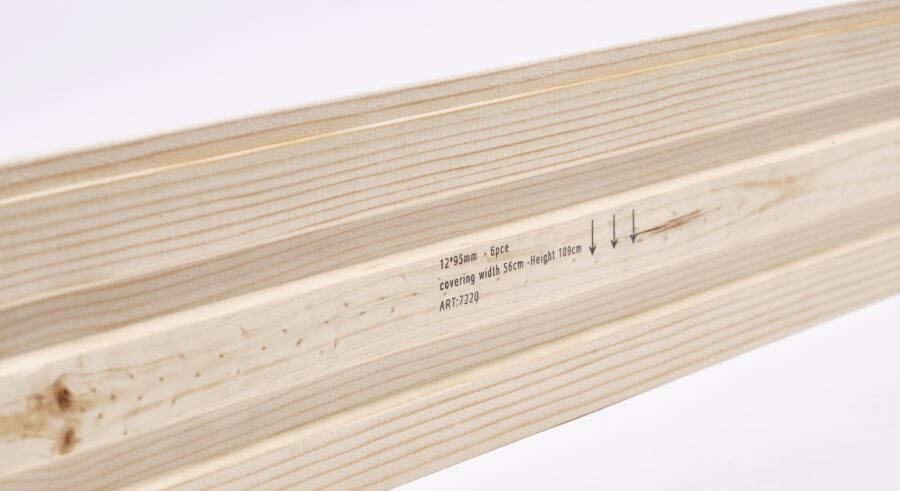

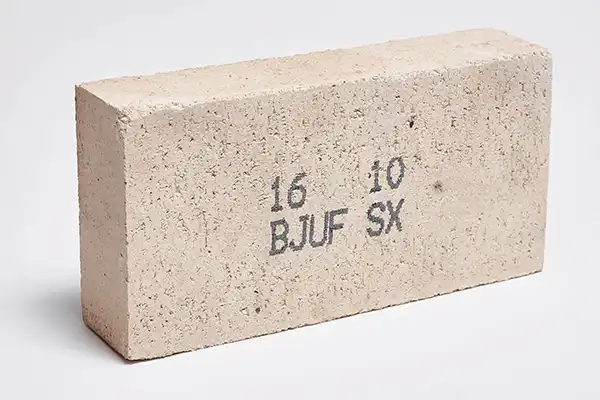

Our V-Series DOD valvejet printers are the most reliable in the industry for marking on a challenging substrates like wood, metal, ceramics and plastic bags. They’re rugged enough to withstand the harshest of manufacturing environments. With the V-Series, you’ll be able to mark in big, bold alphanumeric characters and zero-contact printers can run for 9 billion cycles before they need tuning — the longest printhead life in the industry.

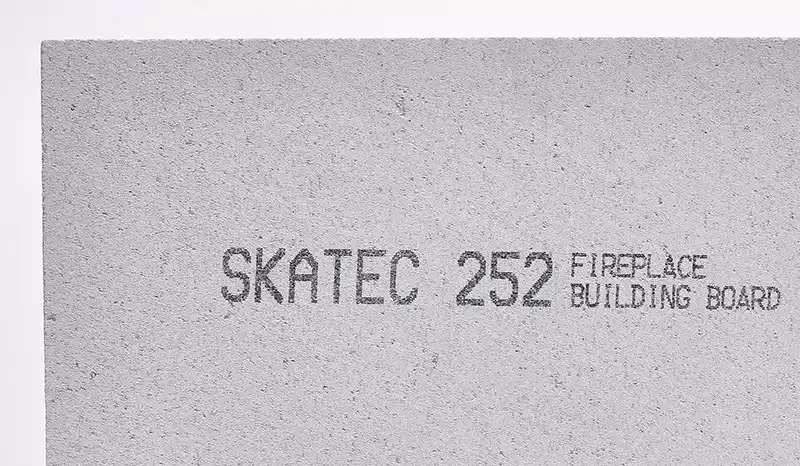

For high-resolution applications like printing on kraft facing, wall board, backer board, XPS foam and cardboard, our L-Series TIJ printers are up to the task with up to 600 dpi resolution and support for lines speeds up to 1,600 ft./min.

For printing barcodes, 2D codes and other information on labels, our MPERIA® A-Series automatic print and apply labeler enables consistent, error-proof, and precise label placement with an advanced safety design that eliminates the need for bulky cages and bolt-on protection systems. And its compact frame fits in most, if not all, confined spaces on your production floor.

Matthews delivers where it matters most

Durability: Our MPERIA V-Series drop-on-demand (DOD) valvejet printers represent the most robust and versatile inkjet marking technology available on the market today. They have been well proven worldwide to withstand the harsh conditions found in wood, metal, fiberglass, ceramics and other production environments.

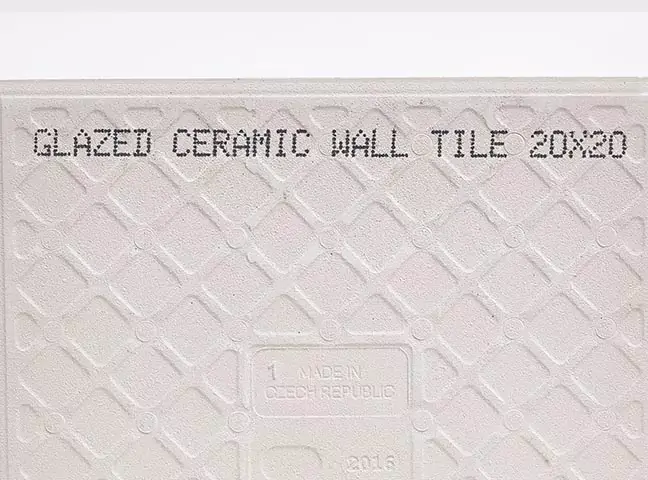

Quality: Different materials or substrates, such as plastic, paper, foam or woven materials, require different marking and coding techniques. Because they never touch the surface and have a long throw distance, valvejet and inkjet printer technologies offer clear advantages for marking applications on a wide variety of surfaces, whether they’re smooth, curved, porous, non-porous, uneven or rough. Valves flush automatically, preventing build-up of residue that can cause bad marks.

Compliance: The building products industry is subject to ASTM, UL, AAMA, NFPA, ISO and other standards for product quality, safety and performance that may require clear, readable product marks to show compliance. In addition, many industries benefit from showcasing environmental certifications like FSC, SFI and GREENGARD to meet the requirements of discerning customers.

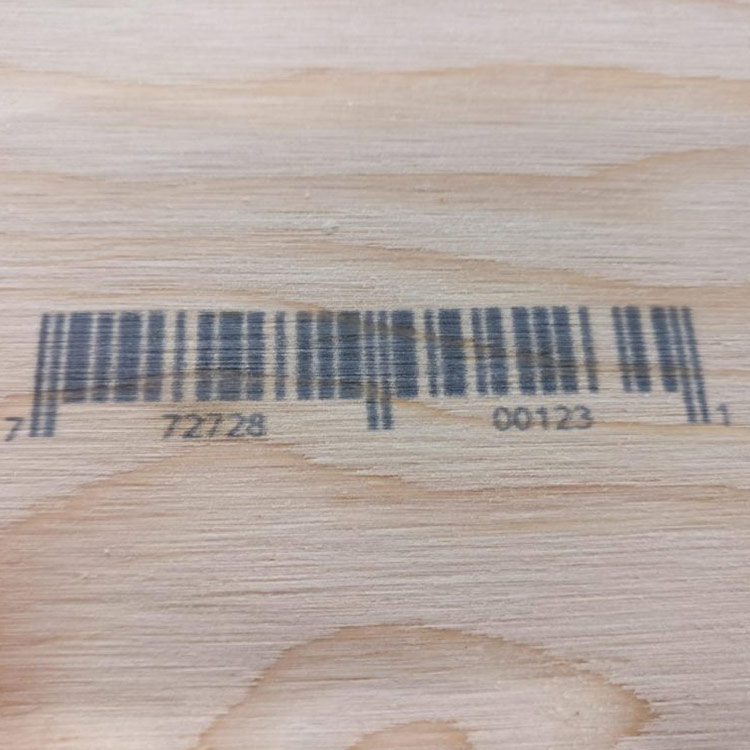

Traceability: Marking of identification codes, barcodes and 2D codes are critical for both internal (production tracking and automation) and external traceability through the supply chain. When a product or component is recalled, clear, crisp, highly readable barcodes are essential. Smeared or unreadable codes can result in costly legal action as well as misplaced, misrouted and unsold items that aren’t correctly inventoried.

Efficiency: Valvejet printers use (and waste) less ink than contact printing methods like stamps, stencils and roller coders used in manufacturing of wood, metal and other building materials. DOD valvejet printheads are impervious to dust and dirt, and less ink accumulates on equipment – meaning less cleaning, less labor, and more savings.

Low maintenance: Matthews V-Series printers are the lowest maintenance industrial marking equipment on the market, with features like fast start-up, bulk ink delivery systems, and automated valve flushing.

Flexibility: Printers with compact printheads can be mounted over, under and beside lines or on traversing systems to give you ultimate control, even on oddly shaped products.

Velocity: Automated control with MPERIA makes message changeovers and updates a breeze. Your lines move faster and more efficiently because you don’t have to regularly stop production to manually reset messages, clean messy equipment or conduct maintenance. With a Matthews solution in place, you’ll never need to slow down because your marking system can’t keep up.

Future-proof your marking technology

High quality marks ensure accurate identification and proper handling of your product – from manufacturing through final use no matter your current or future application:

- Product identification

- Internal and external traceability

- Automation and manufacturing processes

- Location and orientation marking

- Defect marking

- Brand identification

- Barcodes

- Specifications, standards, and structural ratings

- Product certifications

All of these depend on having clear, accurate, and durable marks.

Inks that meet the highest standards

Selecting the right ink is vital to ensuring marks end up in the correct place and stay there for as long as needed. We offer a wide variety of ink types for marking on different substrates, and our in-house ink engineering team can create custom ink formulations to meet virtually any requirement.

Custom solutions designed for you

The number of building products and materials available today is vast. But every product sold needs some sort of marks or labels. More often than not, marking needs to be adapted to fit your requirements and to ensure the long-term reliability you expect.

We’ve seen it all and our engineering experts can customize our products to fit your specifications – not the other way around. From custom kick brackets that can snap out of the way, to traversing systems that move printheads around oddly shaped surfaces to flexible print mounts that can raise and lower print heads to suit varying thicknesses. Bottomline: we create the system that works for your needs.

Take control of your marking and coding operations

Coding and marking requires a print controller that puts you in control. Our MPERIA controllers seamlessly integrate with virtually any coding equipment, data file or enterprise system. You can easily manage and control marking at every stage of production. And your production staff only needs to be trained on a single system to start jobs, manage message changeovers, and resolve issues.

With its flexible architecture, MPERIA keeps integration costs down and makes equipment upgrades easy. Unparalleled system performance allows you to expand your marking capability without significant capital expenditures as your production grows. And like our valvejet and inkjet printer technology, it’s built to withstand the harsh milling and manufacturing environments of the building products industry.

Extreme Reliability with V-Series DOD Inkjet Printers

Recommended Products

OEM marking solutions for equipment providers

If you supply processing tools and fabrication equipment to building product manufacturers, it’s easy to add value by integrating the industry’s most reliable marking solution. Our MPERIA OEM software controller is simple to integrate yet sophisticated enough to delight your most demanding customers. We’re your partner for customized solutions that can grow with your product line. Likewise, we have turn-key solutions for many applications.