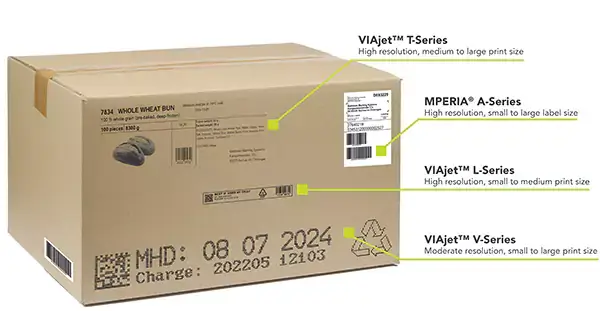

Automated Labeling Machine

Unleash precision and efficiency in labeling with the MPERIA® A-Series. Elevate your production line with superior label placement and safety.

Easy Labeling for Smart Productions

The MPERIA A-Series is an automated print and apply labeling machine designed to streamline your production line with optimized labeling with the MPERIA Platform. Tool-free consumable replacement, a simple paper path with fewer moving parts, an advanced safety design, and the compact frame all deliver precise label placement on every single package, carton, or pallet.

Legacy Print and Apply Challenges

Production lines and operations struggle with their current labeling solutions. Challenges include complexity, high costs, and the need for bulky cages to ensure worker safety. Existing labeling systems often fail to provide the required efficiency and precision in label placement, leading to errors, line stoppages, and quality issues. As a result, there is a growing demand for a labeling solution that is simpler, more cost-effective, and ensures exact labeling without compromising on safety.

The Smart Choice for Automated Print and Apply Labeling

With the MPERIA A-Series, you will enjoy a labeling machine that streamlines your processes, reduces costs, eliminates complexity, and enhances overall efficiency. Get rid of cumbersome and expensive labeling systems – our labeling machine is the ideal choice for companies seeking a reliable, precise, and user-friendly solution that includes:

- Error proof production with accurate and reliable labeling on every package or carton, including pallets

- Multiple applicators and configurations for virtually any production line ensure your label hits the mark

- Precise labeling at the speed of your production line with 8” per second all the way up to nearly 12” per second

- No need for bulky cages or bolt-on protection systems thanks to fewer moving parts and trap points

- Auto-retract feature for applicators and motorized stand ensures worker safety

- Seamlessly integrate label verification and validation without expensive middleware

Amazing Automated Labeler: A Quick 90-Second Guide

MPERIA® Controller and Platform

Consumables are easily replaced with unrestricted access and a simple paper path. Installation is far easier in confined spaces thanks to a compact frame and single-piece construction. Line operators need only learn one controller. The MPERIA controller enables easy message creation/changeover as well as integration with business systems, vision, 3rd party coding technologies, and more.

A-Series D43 Printer

The small size of the A-Series D43 labeling machine is ideal for integration in various production lines or packaging machines. Direct thermal labels are commonly used in the food industry but also for other applications where there are no extreme demands on long storage. DT technology requires only one media type, making it the easiest technology to use.

- Printing Technology: Direct Thermal (DT) technology

- Maximum print width/media width: 108 mm/120 mm

- Label size (W x L): 30×20 mm to 118×240 mm (applicator specific)

- Resolution: 300 dpi

- Print speed: standard up to 200 mm/s, optional up to 300 mm/s

A-Series T43 Printer

Thermal transfer technology is often used in applications where the labeled product requires long shelf life or is exposed to tough handling. Examples are pharmaceutical, industrial and other non-food products. The A-Series T43 labeling machine guarantees excellent barcode readability even after long storage periods.

- Printing Technology: Thermal Transfer or Direct Thermal

- Maximum print width/length: 108 mm/ 240mm

- Label size (W x L): 30×20 mm to 118×240 mm (applicator specific)

- Resolution: 300 dpi

- Print speed: up to 200 mm/s

A-Series T63 Printer

The A-Series T63 labeling machine prints up to A5 format labels and meets the GS1 standards for pallet labeling, and is suitable for pallet and box labeling using large labels carrying a lot of data. The solid aluminum chassis is machined as one piece for perfect alignment of the wide label and transfer rollers, printhead, etc. This eliminates the need for mechanical adjustments and secures high quality printing over time.

- Printing Technology: Thermal Transfer or Direct Thermal

- Maximum print width/length: 162 mm/ 180 mm

- Label size (W x L): 80×20 mm to 178×240 mm (applicator specific)

- Resolution: 300 dpi

- Print speed: up to 200 mm/s

Brochure

About A-Series

The MPERIA A-Series print and apply system is simplicity in its finest form; enabling consistent and precise label placement with an advanced safety design in a compact frame that enables easy installation on your production line—even in confined spaces.

FAQ's

What is the MPERIA A-Series print and apply label system?

The MPERIA A-Series print and apply label system is an industrial label print and apply system designed to provide accurate and reliable labeling on packages, cartons, and pallets in various production lines.

How does the A-Series ensure precise label placement?

The A-Series offers configurations for virtually any application or production line. A wide variety of applicator pads and its compact frame allow installation in the tightest of spaces, ensuring labels are placed where they need to on your packages, cartons, and pallets.

What are the safety features of the MPERIA A-Series?

The MPERIA A-Series has improved safety features, including a minimal number of moving parts and intelligent control to reduce trap points. These features help reduce the risk of injury and eliminate the need for bulky cages or bolt-on protection systems.

Is the installation process easy?

Yes, the A-Series is designed for easy installation. It offers flexible mounting options, and pre-loaded test layouts make setup quick and simple. Additionally, the MPERIA controller’s intuitive touchscreen provides an operator-friendly interface.

Can the A-Series be integrated with label verification and validation systems?

Yes, the A-Series can seamlessly integrate label verification and validation without the need for expensive middleware. This helps ensure accuracy and quality control in your production environment.

Is the A-Series suitable for carton labeling?

Yes, the A-Series is ideal for carton labeling. With its precise label placement and multiple applicator configurations, it ensures accurate and reliable labeling on every carton. The system can handle a range of label sizes (30×20 mm to 118×240 mm) specific to the applicator, making it versatile for different carton sizes.

Is the A-Series suitable for pallet labeling?

Yes, the A-Series is well-suited for pallet labeling. It offers the A-Series T63 printer, which meets the GS1 standards for pallet labeling. This printer can handle larger label sizes (80×20 mm to 178×240 mm) and is designed for pallet and box labeling that requires carrying a significant amount of data. The A-Series ensures high-quality printing over time with its solid aluminum chassis and eliminates the need for mechanical adjustments.

Support Documents

MPERIA® A-Series

Experience the future of labeling with the MPERIA A-Series.

Streamline your production line with optimized labeling, tool-free consumable replacement, and an advanced safety design. Say goodbye to complex and costly solutions – request a demo now to see how our precise label placement can transform your operations. Fill out the form below and take the smart step towards efficient and reliable labeling.