Stone

Getting clean, clear long-lasting marks on stone and brick products can be tricky. With industry leading reliability and proven performance under the harshest conditions, our inkjet and labeling solutions are more than up to the task.

Marking and Coding Solutions for the Brickworks and Stone Industry

As an industrial producer, your inks and marking equipment need to work reliably in highly challenging manufacturing environments. Porous and non-porous materials, uneven and oddly shaped surfaces, dust, residue, hot and cold temperatures can all dramatically affect print quality.

Whether you’re printing product identification specs, lot numbers, batch or 2D codes directly on brick or stone; automatically placing labels on pallets; or showcasing your brand with big, bold trademarks, Matthews offers a line-up of workhorse, drop-on-demand (DOD) valvejet and inkjet printers and print and apply labelers that give you great flexibility while standing up to the toughest conditions of your manufacturing environment.

Command and Control Your Production Goals With Drop-on-Demand Inkjet Printing

Boost your production and business results

Choosing the right print technology can have a positive impact on your bottom line. The type of technology you use for marking and coding on building products affects the:

- Speed and efficiency of your marking and coding

- Quality, accuracy and reliability of your marks

- How much ink you use (or waste)

- Labor and time required for changeovers

- Amount and interval of maintenance required

- Business and supply chain velocity

- Ability to quickly expand production

You need a marking solution that reliably delivers high quality marks on porous and non-porous materials, in the toughest of environments, and can easily adapt to new requirements as your operation grows and evolves.

No other printing technology offers the reliability, convenience and cost savings of modern DOD valvejet printers and inkjet printers for direct product marking or for marking on bags filled with gravel or other materials. These systems are also well-suited for marking directly on corrugated or plastic shipping cases and containers.

For shipping finished goods on pallets, our automated print and apply labeling machines ensure accurate placement of shipping and tracking labels.

Industrial marking technology you can count on

Matthews has a long tradition of offering industrial marking and coding products that are rugged, efficient, and reliable, producing marks of unmatched quality on a wide variety of substrates. We’ve literally seen it all.

The marking and coding needs of the brickworks and stone industry are as varied as the materials themselves.

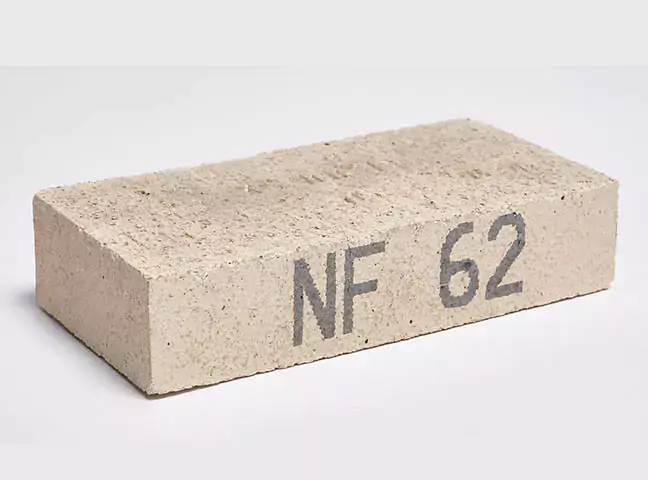

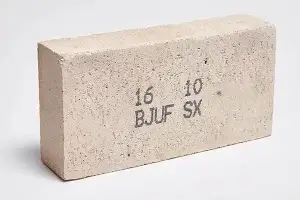

- Brick

- Concrete bricks and pavers

- Clinker

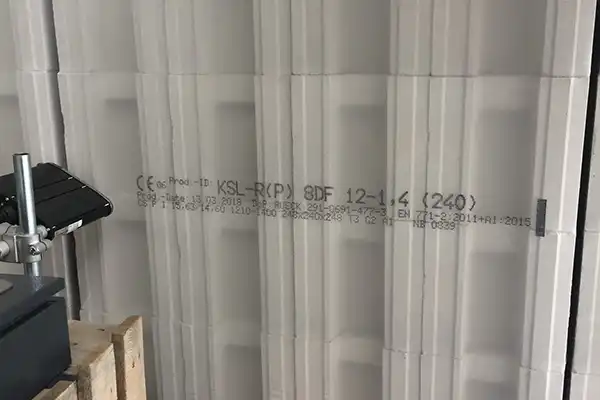

- Autoclaved Aerated Concrete

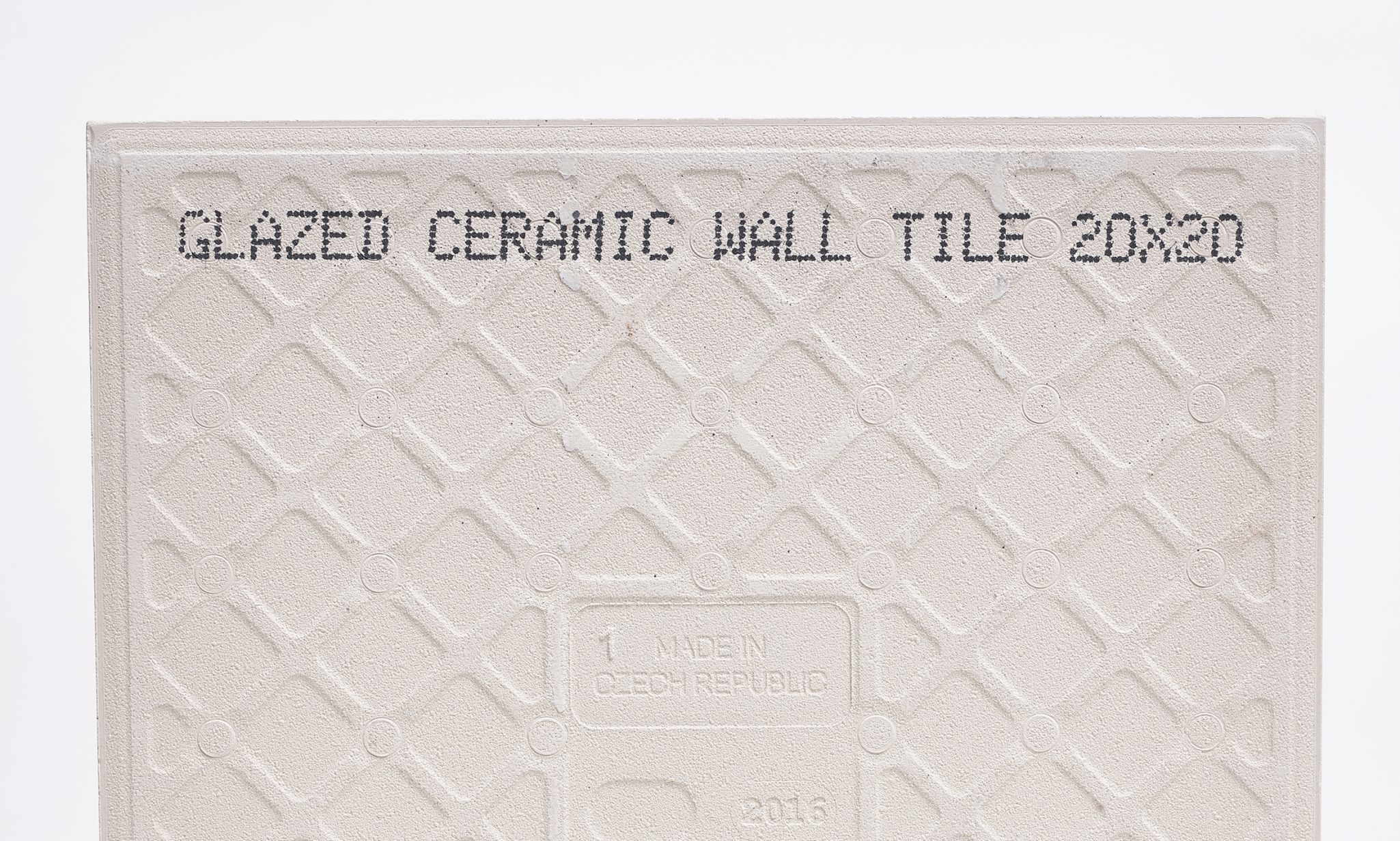

- Tiles

- Granite and stone slabs

- Bags and big bags

- Pallets

- And much more…

With Matthews inks and printers, you’ll get consistently clean, legible marks and codes on your brickwork, stone and bagged products, and you’ll reap the business benefits of greater flexibility, reduced costs, and proven reliability – without the maintenance headaches.

Our V-Series DOD valvejet printers are the most reliable in the industry for marking on a challenging substrates like ceramics, concrete and stone. They’re rugged enough to withstand the harshest of manufacturing environments. With the V-Series, you’ll be able to mark in big, bold alphanumeric characters and zero-contact printers can run for 9 billion cycles before they need tuning — the longest printhead life in the industry.

For high-resolution marking application such as 2D barcodes, our L-Series TIJ printers are up to the task with up to 600 dpi resolution and support for lines speeds up to 1,600 ft./min.

For applications that require labels instead of direct marking, our MPERIA® A-Series automatic print and apply labeler enables consistent, error-proof, and precise label placement with an advanced safety design that eliminates the need for bulky cages and bolt-on protection systems. And its compact frame fits in most, if not all, confined spaces on your production floor.

Durability

Our solutions have been well proven worldwide to withstand the harsh conditions found in brickworks, concrete, stone and other dusty production environments.

Quality

Different materials or substrates require different marking and coding techniques. Because they never touch the surface and have a long throw distance, valvejet and inkjet printer technologies offer clear advantages for marking applications on a wide variety of surfaces, whether they’re smooth, curved, porous, non-porous, uneven or rough. Valves flush automatically, preventing build-up of residue that can cause bad marks.

Efficiency

Valvejet printers use (and waste) less ink than contact printing methods like stamps or stencils used in manufacturing of brickworks and stone products.

Reliability

Matthews V-Series printers are the most reliable industrial marking equipment on the market, with features like fast start-up, bulk ink delivery systems, and the ability to achieve over 9 billion firings before tuning is required.

Flexibility

Printers with compact printheads can be mounted over, under and beside lines or on traversing systems to give you ultimate control, even on oddly shaped products.

Velocity

Featuring an intuitive touch-screen interface and centralized control, our MPERIA controller makes message changeovers and updates a breeze. Your lines move faster and more efficiently because you don’t have to regularly stop production to manually reset messages, clean messy equipment or conduct maintenance. With a Matthews solution in place, you’ll never need to slow down because your marking system can’t keep up.

Inks that meet the highest standards

Selecting the right ink is vital to ensuring marks end up in the correct place and stay there for as long as needed. We offer a wide variety of ink types for marking on different substrates, and our in-house ink engineering team can create custom ink formulations to meet virtually any requirement.

Marking solutions designed for you

The number of building products and materials available today is vast and evolving steadily. In many cases, a one-size fits all solution won’t work and your marking solution will need to be adapted to fit your requirements.

We’ve seen it all and our engineering experts can customize our products to fit your specifications – not the other way around. From custom kick brackets that can snap out of the way, to traversing systems that move printheads around oddly shaped surfaces to flexible print mounts that can raise and lower print heads to suit varying thicknesses. Bottomline: we create the system that works for your needs.

Take control of your marking and coding operations

Coding and marking requires a print controller that puts you in control. Our MPERIA controllers seamlessly integrate with virtually any coding equipment, data file or enterprise system. You can easily manage and control marking at every stage of production. And your production staff only needs to be trained on a single system to start jobs, manage message changeovers, and resolve issues.

With its flexible architecture, MPERIA keeps integration costs down and makes equipment upgrades easy. Unparalleled system performance allows you to expand your marking capability without significant capital expenditures as your production grows. And like our valvejet and inkjet printer technology, it’s built to withstand the harsh production environments of the stone and brickworks industry.

OEM marking solutions for equipment providers

If you supply tools and equipment to stone and brickworks manufacturers, it’s easy to add value by integrating the industry’s most reliable marking solution. Our MPERIA OEM software controller is simple to integrate yet sophisticated enough to delight your most demanding customers. We’re your partner for customized solutions that can grow with your product line. Likewise, we have turn-key solutions for many applications.