Bag Marking

Get the most readable, scannable marks and codes on your bags every time with low-maintenance, high-performance printers that can operate in any environment.

Reliable Solutions for Bag Marking and Coding

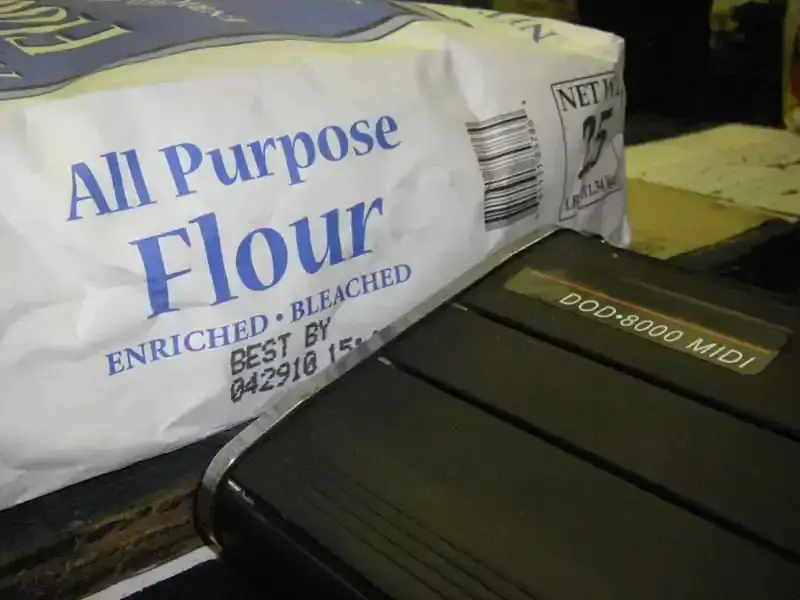

Countless consumer and industrial products come delivered in bags, pouches and other types of flexible packaging in all shapes and sizes. And in contrast to the rigidity and conformity of cardboard boxes, the variety of types of bags and pliability of each substrate mean that careful consideration must be paid to marking and coding processes.

In addition, temperature fluctuations, vibration and uneven shapes and sizes are more the rule than the exception on manufacturing floors. So printing and labeling solutions for bags need to be versatile and able to withstand a variety of sub-optimal conditions. Fortunately, Matthews’ offers the most reliable inkjet printing solutions in the industry that more capable of withstanding the harshest of manufacturing environments.

With Matthews you can rest assured that your printers will hit the mark every time with minimal maintenance requirements and consistent, error-proof, and precise placement of long-lasting durable marks and codes on all types of bags.

Reliable marking even when the going gets tough.

Overcoming marking challenges

With the rise and importance of product traceability globally, it’s more important than ever that bagged products are marked accurately and consistently during the production process. But this isn’t as easy as it sounds. Marking on bags comes with its own set of challenges, including:

Uneven or textured surfaces

Bags have different surface textures (e.g. smooth or rough), and can be porous or nonporous. Some of these surfaces can pose challenges for printing or labeling processes, as they may require the use of specialized inks capable of adhering to slick or shiny surfaces.

Timing of the fill

If printing takes place before the bag is filled, you’ll have more consistency and flat, even surface areas to work with. But more often than not, marks and codes are printed post fill. This can result in uneven shapes and print areas and often requires the use of custom guides and rails to obtain consistent results.

Harsh environments

The importance of managing harsh conditions can’t be overstated. The production floor can expose marking and labeling machines to a variety of difficult environmental conditions such as dust, heat, humidity, or chemicals. These factors directly affect both mark quality and equipment reliability if they aren’t managed correctly.

Bag materials

Different bag materials or substrates, such as plastic, paper, or woven materials, require different marking and coding techniques. The manufacturing environment determines the choice of materials based on factors like durability, product protection, and cost. The chosen material may affect the type of ink or labels or printing method used for marking and coding.

Fortunately, Matthews has printing technologies and the required expertise to address all of these challenges and more, ensuring that your bags are marked perfectly each and every time.

The global leader for marking solutions

Matthews has decades of experience producing high quality, clean, readable marks on almost any substrate under virtually every condition.

Our V-Series DOD valvejet printers are the most reliable in the industry for marking on bags, and rugged enough to withstand the harshest of manufacturing environments. With the V-Series, you’ll be able to mark in big, bold alphanumeric characters and can run for 9 billion cycles before they need tuning — the longest printhead life in the industry.

For high-resolution applications, our L-Series TIJ printers are up to the task with up to 600 dpi resolution and support for lines speeds up to 1,600 ft./min.

In addition, our MPERIA® A-Series automatic print and apply labeler enables consistent, error-proof, and precise label placement with an advanced design that eliminates the need for bulky cages and bolt-on protection systems. And its compact frame fits in most, if not all, confined spaces on your production floor.

Take control of your bag marking and coding operations

Bag coding and marking requires a print controller that puts you in control. Our MPERIA controllers seamlessly integrate with virtually any coding equipment, data file or enterprise system. You can easily manage and control marking at every stage of production. And your production staff only needs to be trained on a single system to start jobs, manage message changeovers, and resolve issues.

With its flexible architecture, MPERIA keeps integration costs down and makes equipment upgrades easy. Unparalleled system performance allows you to expand your marking capability without significant capital expenditures as your production grows. And like our valvejet and inkjet printer technology, it’s built to withstand harsh milling and manufacturing environments.

Comprehensive ink solutions

Matthews is a one-stop-shop for your ink and equipment needs, which means we can partner with you to ensure your equipment and ink add up to the most reliable total solution for your applications possible. If we don’t have it, we’ll customize an ink for your substrate. Our inks have been tested across a wide range of temperatures to deliver the highest marks quality, the lowest maintenance requirements and to maximize printer performance and reliability.

Recommended Products

FAQ's

What factors do I need to consider when purchasing printers for bag codes and marks?

Bag coding and marking comes with its own set of challenges. When purchasing or upgrading your bag marking machines or preparing to add bag marking to your production line, you’ll want to consider:

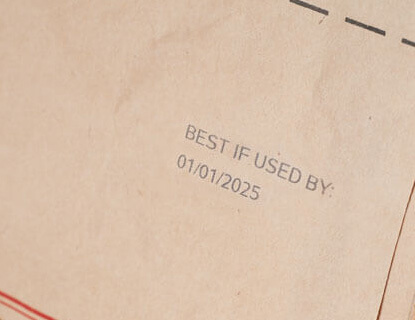

Print durability: Marks and codes applied to the bags must withstand whatever abuse they will face after the production. For this reason, you should always obtain and test sample marks on the bags you’re marking.

The types of codes or marks: While some marks may be more for the consumer or for simple identification purposes, others must be very clearly readable and scannable as they play a key role in inventory, tracking, and traceability.

Throw distance: Most bags are marked post-fill resulting in uneven shapes and curved or oddly shaped surfaces. Marking on curved surfaces requires printers with longer print or throw distances.

Printing speed: As speeds ramp up, some printing technologies may struggle and/or mark quality can suffer.

Ink selection: Choosing the right ink for your printer and bag substrate helps to maximize quality, reduce the cost per mark, and ensure reliable equipment performance.

What are the consequences of poor bag marking?

Poor bag marking can lead to a host of costly issues, both to your bottom line and your reputation. Three of the most common include:

Marking errors: Bottlenecks and unplanned downtime can wreak havoc on your production lines’ overall equipment efficiency and cost your company thousands or even hundreds of thousands of dollars a day. In addition, if marks are not clear or consistent or the wrong marks are on the wrong bags, re-marking bags can be a significant waste of time and resources.

Poor legibility: Barcodes that are unable to be scanned or are unreadable due to smudged or missing information may have difficulties being traced through the supply chain process. This can result in delays, confusion and lost inventory. In addition, you may face issues verifying the authenticity of your products and open a door for counterfeiters.

Compliance issues: Marks and codes that are missing or unreadable may violate compliance and/or safety regulations, which may mean legal repercussions, penalties, and/or expensive fines for your organization. In addition, poor batch marking can lead to costly issues in the unfortunate event of a product recall.