Pallet Labeling System

Eliminate the headaches of pallet labeling by upgrading to an innovative, precise, and safe print-and-apply labeler that hits the mark every time.

Accurate and Precise Pallet Labeling Starts Here

Once your products are ready to go to market, there is no room for error when it comes to packaging and labeling. The strict, yet different, pallet labeling requirements mandated by major retailers mean that any mistakes could result in costly fees or even pallets of goods being rejected or returned.

What’s the best way to make sure the right labels end up on the right pallet in the right location every time? Simply put, the Matthews MPERIA A-Series T63 automatic labeling machine. The A-Series is engineered to safely and precisely print and apply labels on pallets as they come off your production lines. Even better, simple, tool-free maintenance of printheads, rollers, and drive belts set you up for sustained success. In addition, system longevity is maximized, while failure points are minimized (even in challenging environments) thanks to the single-piece, solid-construction frame, sealed ball bearings, and brushless DC motors.

Amazing Automated Labeler Machine: A Quick 90-Second Guide

MPERIA® Controller and Platform

Tap into new ROI opportunities

Before moving ahead with new equipment purchases or process changes, smart manufacturers look closely at the anticipated return on investment (ROI). For many manufacturers, pallet labeling represents an untapped opportunity to lower costs, increase efficiency, reduce errors, and ultimately realize a rapid ROI.

This is because the latest generation of print and apply labeling machines, such as the MPERIA A-Series, have advanced the state-of-art considerably. With this in mind, you’ll want to take a hard look at your current labeling process and technology – including hand labeling – to determine if your needs are truly being met and how quickly you could achieve payback.

Industry leading pallet labeling technology

A-Series T63 labeling stacked pallets

With the MPERIA A-Series T63 with FlexWipe applicator, Matthews delivers a pallet labeling solution that streamlines your processes, reduces costs, eliminates complexity, and enhances your overall efficiency. Our small-footprint solution is the ideal choice for companies seeking a reliable, precise, and user-friendly print and apply labeling solution that includes:

- Accurate and reliable labeling and verification on every package or case, including pallets

- Multiple applicators and configurations for virtually any production line ensure your label hits the mark

- Precise labeling at the speed of your production line with 8” per second all the way up to nearly 12” per second, and up to five pallets per minute labeled

- No bulky cages or bolt-on protection systems required – minimal moving parts and intelligent sensors keep workers safe

- Seamless integration for label verification and validation without expensive middleware

- Automatic labeling up to three sides

- Easy, tool-free maintenance, and a small footprint

- The ability to withstand tough environments (operation to -18°F), as well as rough, uneven and/or cold surfaces

- GS1-compliant labeling

- A motorized stand, allowing for accurate label placement on stacked pallets or incomplete pallets

Automated marking made easy

The scalable, extensible MPERIA platform allows manufacturers to easily create the right formats for shipping to large-scale retailers like Amazon and Walmart and automate the process to create, code, verify, and change messages for pallets.

The MPERIA platform also allows companies to centrally control a single or multiple printers and labeling systems across single or multiple production lines, including vision systems, third party printers, labelers and other equipment. MPERIA also makes it easy to integrate with ERP and back-office systems to minimize errors and enhance traceability across the supply chain.

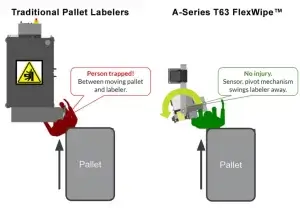

Safety is the name of the game

You don’t have to incur the extra expense and inconvenience of installing cages or bolt-on protection with the A-Series. Minimal moving parts and intelligent sensors keep workers safe. For instance, if an operator or production line worker accidentally moves between the applicator and pallet as the A-Series activates, the applicator arm switches off immediately and retracts. The entire labeler swings out of the danger area.

Easy tool-free maintenance, less downtime

Maintaining and servicing the A-Series is a breeze. The printhead, rollers, and drive belts are easily accessible and don’t require tools. A label change-out can be finished in as little as 20-seconds.

Flexible in every way

Flexible in every way

The FlexWipe applicator on the A-Series rotates 360 (degrees) giving you ultimate flexibility. Marking in 4 positions is effortless thanks to independent control and multiple stepping motors. Since the A-Series takes up less than a square meter (3.3ft²) of floor space, integration headaches with your existing production lines are a thing of the past.

With its motorized stand, the A-Series can label both stacked and incomplete pallets. Whether your pallets are stacked two-high or the last of your production means an incomplete pallet, the A-Series handles it with ease.

Validate your label regardless of rough conditions

Assurance comes standard when labeling with the A-Series. An integrated camera system on the applicator automatically ensures printed codes are legible, giving you confidence in your traceability initiative. Additionally, brushes on both sides of the applicator pad make certain that the label is successfully applied – even when the surface is rough, uneven, or cold.

Frigid temps? No problem!

Say goodbye to your cold-storage labeling headaches, the A-Series excels when it’s icy. Excellent operation when the temps drop to -18°F (-28°C) without the need for heaters or special housing.

Recommended Products

FAQ's

What should I look for when purchasing labeling technology?

When you decide to make the move to automated print-and-apply labeling – or upgrade to better equipment – there are a number of things to consider. We recommend diving deep into the following areas when investing in labeling technology:

Flexibility: Any labeling tech you purchase should allow for maximum flexibility, in terms of size, fit on the line, and application. You want a machine that allows the operator to make adjustments on the fly, monitor those changes, and recall them quickly as needed.

Safety: You will want to look for technology that doesn’t require safety cages or guarding and can easily fit into any existing production infrastructure with no additional safety precautions.

Simplicity: Before purchasing, ask for a demo of the equipment and have an honest conversation about the level of training required for operators to run the machines. Moving to automated print-and-apply labeling should decrease the level of work needed, not add to it.

Reliability: When making this investment you should be sure that both the machines and the support systems behind them are designed to be reliable and long lasting. In addition, you’ll want to ask about quality control and assurance of the technology you are buying.

Integration with other systems: For labeling technology to show its true worth, it should be able to integrate with other systems to share data. Having a centralized command center ensures consistency along the line and provides a singular place where information is managed.

I have labeling equipment that was purchased a few years ago. Why should I upgrade?

In recent years, equipment suppliers have upped the ante with better, faster, safer, and more flexible LPA (label printer applicator) technology. Exploring these new systems by conducting informational meetings with suppliers can help you determine if:

- Your current technology is hitting the mark or if it’s costing you money through printing or placement errors, scrapped products, and/or regulatory violations.

- Slow message changeover and/or maintenance issues could be setting your organization back hundreds of hours a year in equipment downtime.

- The training and labor required to run your current labeling technology is wasting valuable time that could be applied to tasks that require more critical thinking skills. Today’s modernized LPAs are intuitive, user-friendly, and have more streamlined navigation and tools, and allow for much faster and simpler installation, operation, and maintenance.

- You have the right amount of visibility and insight into printer performance, or if you are missing key data to make continuous improvements across the entire line.

Why should I switch to automated pallet labeling when hand labeling seems to work just fine?

The time-consuming and manual task of hand labeling leaves ample room for human error. This can lead to more downtime. In addition, paying workers to stick a label on a box or pallet isn’t a cost-effective way to do business and doesn’t scale, especially if you are experiencing labor shortages in other parts of your process.

As reference, let’s do a quick review of the benefits of automated print-and-apply labeling versus hand labeling:

Cost and scalability: Automated labeling may have a higher upfront investment in the technology, but long term you’ll get more bang for your buck, especially if your business grows in any way. Continuing to pay full-time workers for a singular job will likely become cost-prohibitive, with tens of thousands of dollars spent on inefficient labeling methods.

Accuracy and consistency: High quality labeling machines will always be faster and more accurate, efficient, and precise than humans. Labels are placed cleanly and correctly on every carton or pallet with consistency in timing and placement.

Safety: Combining machines and human workers can lead to safety concerns, as workers will be more exposed to fast moving parts. On the other hand, modern labeling technology eliminate the need for safety cages and guarding, and allow for more flexibility and ease of use, decreasing the opportunity for injuries.

Productivity: Due to its speed and efficiency, automated labeling machines can significantly increase productivity on the line. Simple and fast message changeovers result in significantly less downtime. Machines are also faster, less wasteful, and more reliable than humans, resulting in consistent output every time.

Ready to revolutionize your pallet labeling? Request a demo of our automated labeling system.

With the MPERIA A-Series T63 with FlexWipe applicator, Matthews delivers a pallet labeling solution that streamlines your processes, reduces costs, eliminates complexity, and enhances your overall efficiency. Contact us today to learn more or arrange for a demo.