Pipes & Plastics

Reliable, high-performance coding and marking systems for printing on metal and plastic pipe as well as other types of plastic substrates.

Marking and Coding Solutions for Pipes and Plastics

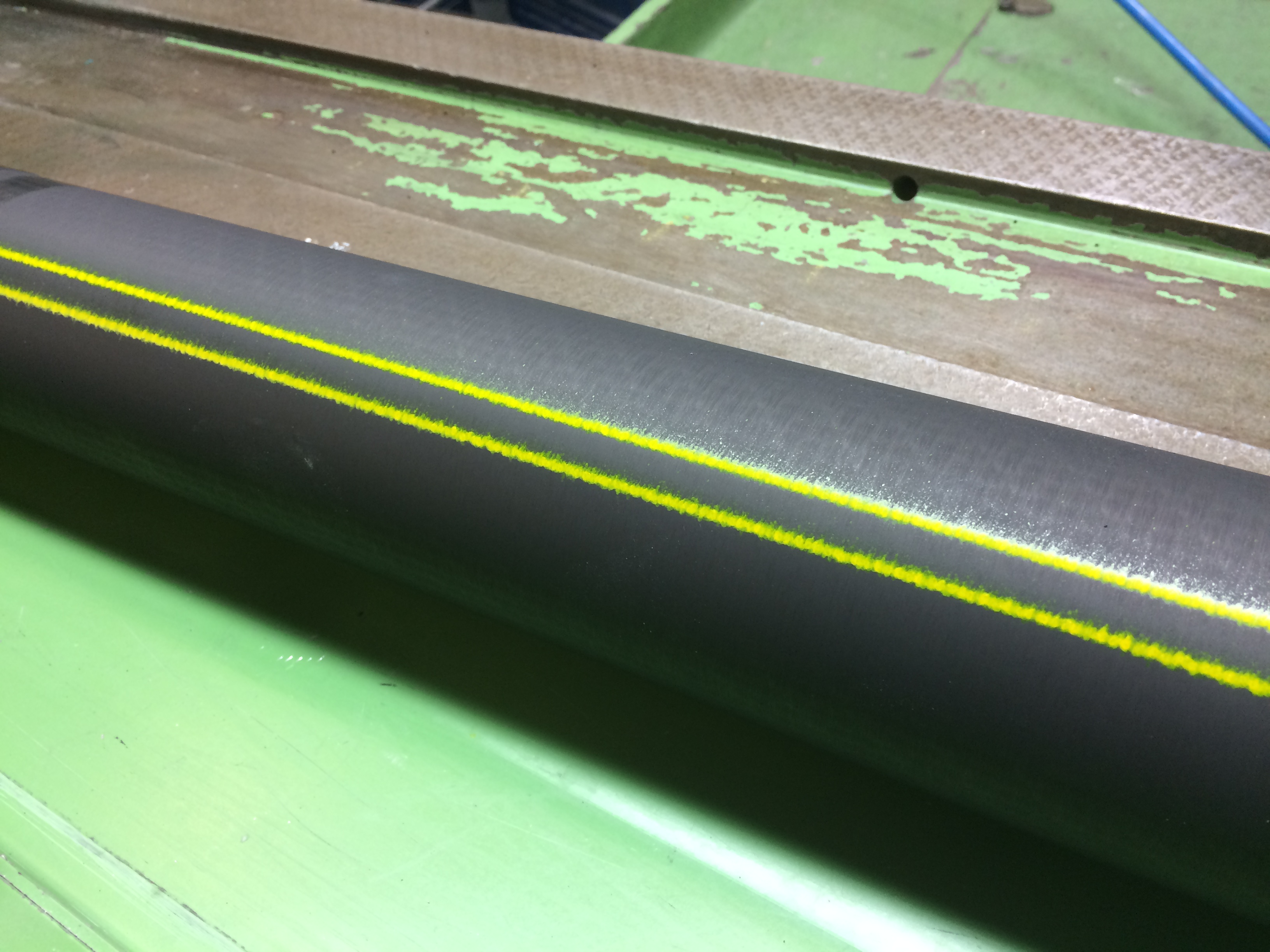

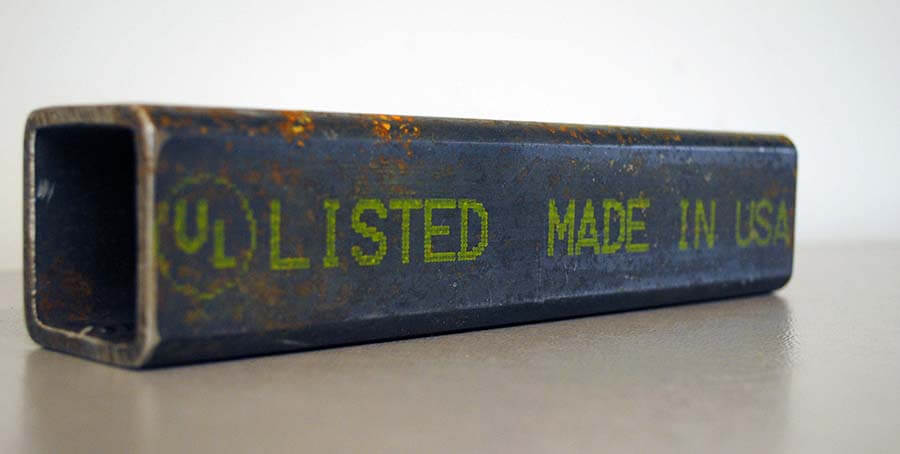

Whether your pipes are metal, plastic, or corrugated, it’s imperative that marks and codes are crisp and high contrast, with ink that stands the test of time. Pipes may be in place for decades and/or be exposed to a variety of harsh elements, such as fluctuating temperatures, humidity, dust, and fluids.

Matthew’s coding and marking systems can be relied on to make sure your products are easily identifiable over their life cycle, with high-quality prints that last. You can rely on our extensive industry knowledge and proven results to help you make your mark. We work closely with the pipe and plastics industry to create comprehensive marking solutions while continually developing new inks and technologies to meet changing production demands.

Command and Control Your Production Goals With Drop-on-Demand Inkjet Printing

The future of pipe and plastic marking technology

Matthews has been working with pipe manufacturers for decades, delivering reliable printing technology and custom ink solutions engineered specifically for metal and plastic tubing as well as many plastics manufacturing applications.

Our V-Series DOD valvejet printers are the most reliable in the industry for large character pipe marking, and rugged enough to withstand the harshest of manufacturing environments. With the V-Series, you’ll be able to mark in big, bold alphanumeric characters without missing a beat: these printers are rated for 9 billion cycles before they need tuning — the longest printhead life in the industry.

For high-resolution and smaller character applications, our L-Series TIJ printers are up to the task with up to 600 dpi resolution and support for high-speed operation.

Tying it all together, our MPERIA controller seamlessly integrates with virtually any coding equipment, data file or enterprise system. You can easily manage and control marking at every stage of production. And your production staff only needs to be trained on a single system to start jobs, manage message changeovers, and resolve issues.

With its flexible architecture, MPERIA keeps integration costs down and makes equipment upgrades easy. Unparalleled system performance allows you to expand your marking capability without significant capital expenditures as your production grows.

Custom solutions adapted to your requirements

One size fits all rarely works in pipe and plastics manufacturing. Traversing systems that can move printheads into large pipes for marking the interior surface? The ability to raise and lower print heads to suit varying thicknesses of steel or plastic? We’ve seen it all and our engineering experts can customize our products to fit your specifications — not the other way around.

Industry leading ink solutions

Matthews is a one-stop-shop for your ink and equipment needs, which means we can partner with you to ensure your equipment and ink deliver the most reliable total solution possible for your line. If we don’t have it, we’ll customize an ink for your substrate. Our inks have been tested across a wide range of temperatures and are guaranteed to work seamlessly in all our printers, ensuring reliability for both the ink and equipment running it.

Our chemists and engineers have a combined 118 years of experience working in the ink industry. Offering research and development, ink production oversight, systems testing, sample marking, and technical support, this team has the experience and know-how to tackle your toughest pipe marking challenges.

In addition, we can test inks as part of a complete solution with the Matthews print technology best suited for your application. This testing is what ensures rock-solid reliability and the highest quality marks, lowering costs and improving overall performance.

OEM marking solutions for equipment providers

If you supply tools and equipment to pipe, tubing or plastics manufacturers, it’s easy to add value by integrating the industry’s most reliable marking solution. Our MPERIA OEM software controller is simple to integrate yet sophisticated enough to delight your most demanding customers. We’re your partner for customized solutions that can grow with your product line. Likewise, we have turn-key solutions for many applications.