From better consumer engagement to more granular inventory management, the move to 2D barcodes points to a brighter future

The familiar 1D barcode we’ve know for decades is transitioning to next generation 2D barcodes, as detailed in our post making way for 2D marks. This transition will unlock exciting new use cases and bring much-needed improvements to supply chain efficiency and traceability. At the core of it all is GS1, the global standards organization for barcodes and administrator of the Universal Product Code (UPC) barcode.

Steven Keddie, senior director of GS1 standards and the GS1 portfolio of automatic identification and data capture technologies

To learn more about the upcoming retail transition to 2D barcodes and the latest developments in barcode standards, Matthews Marking Systems sat down with Steven Keddie, senior director of GS1 standards and the GS1 portfolio of automatic identification and data capture technologies. Read on to learn what’s coming and how it will impact your marking and coding operations.

What is Sunrise 2027, and why is GS1 moving from the traditional barcode to 2D barcodes and GS1 Digital Link URI?

Consumers, brand owners, retailers and regulators: Everyone wants to know more about products. And as a result, everyone is looking for better ways to access information about a product by scanning a code on its packaging.

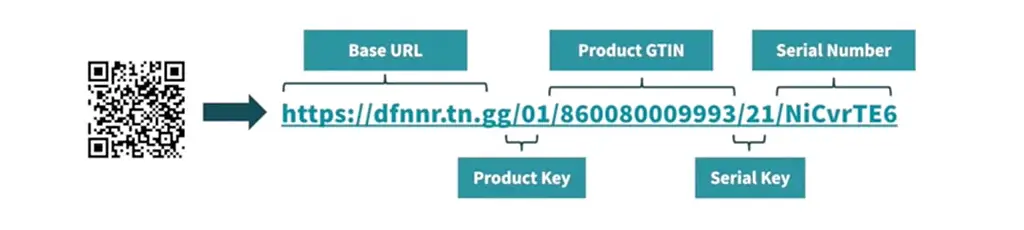

The problem? Most barcodes today provide a very limited amount of information. Traditional barcodes are typically scanned by companies and organizations to access supply chain information for business systems. However, traditional QR codes are typically scanned by consumers to access a webpage with product information. GS1 Digital Link URI syntax embedded in a 2-dimensional (2D) barcode (such as QR codes) enables both consumer and supply chain stakeholders to access unlimited brand-authorized data about products, while also supporting point-of-sale (POS) transactions.

GS1 is partnering with industry leaders to harness the power of the next generation of barcodes (2D barcodes) to not only meet but exceed the increasing demands of shoppers for more product information and do more than trigger a “beep” at the checkout.

This journey will enhance the experiences of consumers, brands, retailers, and everyone in between. GS1 is supporting industry around the world to harness the power of these next generation of barcodes to enable new business solutions for today … and into the future.

Sunrise 2027 is about moving U.S. industry toward enabling 2D capabilities at retail POS, in addition to existing capabilities to read and process 1D EAN/UPC barcodes for price lookups. The U.S. Sunrise 2027 initiative also includes expanding into non-retail health care locations, including places like hospitals, clinicians’ offices, and operating rooms, to get more from the data in the GS1 Data Matrix barcode. While not a Sunrise date, Ambition 2027 is an industry-driven milestone to help the global retail community make 2D barcodes a reality at POS.

What progress has been made across the industry toward making the shift to 2D codes in the past year? What are some pilot projects and initiatives in the works?

The retail industry has been piloting and implementing 2D barcodes (QR codes or Data Matrix) with GS1 Digital Link URI globally. The largest by volume is happening in Zhejiang province in China with over 67,000 companies implementing QR codes (GS1 Digital Link URI), over 5,000 stores scanning 2D barcodes, and approximately 200 million consumers scanning with their smartphones. Australia’s largest retailer has over 9 million fresh food products scanned per day in their store. Some of the world’s biggest brands are beginning to leverage QR codes (GS1 Digital Link URI) on their products for consumer engagement. But the first retailer to adopt and scan a QR code with GS1 Digital Link URI was Parla Deli, a Brazilian gourmet shop.

All of t he retailers and brand manufacturers are seeing wonderful support from the solution-provider community. All major point-of-sale scanner manufacturers have partnered with GS1 in developing and testing solutions to support 2D barcodes in retail migration. In addition, many printing solution providers have supplied samples to support the scanner lab testing at the University of Memphis. GS1 also developed a software library for the solution provider to add to their printers and scanners to help with the conversion between GS1 syntaxes and to ensure the syntaxes are properly structured. These solutions are being used in pilots and implementations globally.

he retailers and brand manufacturers are seeing wonderful support from the solution-provider community. All major point-of-sale scanner manufacturers have partnered with GS1 in developing and testing solutions to support 2D barcodes in retail migration. In addition, many printing solution providers have supplied samples to support the scanner lab testing at the University of Memphis. GS1 also developed a software library for the solution provider to add to their printers and scanners to help with the conversion between GS1 syntaxes and to ensure the syntaxes are properly structured. These solutions are being used in pilots and implementations globally.

Pilots are happening in all retail environments and in almost every region. From apparel and cannabis in North America to prepared meals and whisky in Asia, the migration to 2D is accelerating. GS1 Global Office tracks the pilots/implementations and supports the local GS1 Member Organization through education and making connections to enable their users 2D projects.

What use cases will QR codes and Data Matrix codes with the new GS1 Digital Link standard unlock?

The main opportunities for 2D use cases include:

- Granular inventory management: Items can be managed by expiration date to ensure freshness and reduce waste.

- Sustainability: Recycling info and waste prevention.

- Traceability: Sourcing information for ingredients.

- Consumer engagement: Consumers can scan packages with their smartphones to download an instruction manual or access a how-to video, view allergen information and so much more.

- Safety: Better recall management, such as surgical recall of lettuce and other produce by only the affected batch/lot.

- Improved packaging: Reduction of the number of barcodes on a package, thus freeing up real estate on packaging and reducing confusion by stores and consumers on what should be scanned.

However, each use case can unlock other opportunities. Let’s review how the additional data in 2D barcodes can unlock grocer and consumer use cases.

Granular inventory management example: By adding and capturing the expiration date in a 2D barcode the retailer now tracks the freshness of all perishable products (e.g., vegetables, prepared meals, meat, fish, etc.) from the moment they enter the store until they are sold at the point of sale. This capability can then unlock automatic price markdowns based on product freshness, free up retail staff to focus on customers instead of auditing expiration dates on shelves, capture expired products at the point of sale (consumer safety), and so much more. When you combine the automatic price markdown with the freshness, you can change the consumers buying habit of reaching for the expiration date furthest away. By offering a discount on the produce that’s closer to expiration, the consumer is more likely to take advantage of the savings, which results in food waste reduction and improved sustainability.

Consumer engagement example: One retailer leverages the 2D barcode to inform their customer about the salmon they are about to buy. The shopper scans the 2D barcode with the retailer’s app and the app delivers a wealth of online information:

- Where the salmon was caught (e.g., Alaska, North Atlantic, …)

- How the salmon was caught (e.g., trawl net, gillnets, …)

- Where the fish was processed (e.g., on the ship, in a factory, …)

- The best before date for the salmon

- Recommended recipes and wine pairings

In addition to the obvious changes at the retail and consumer level, how will the shift to 2D barcode bring deeper changes within the supply chain?

As you noted, the current focus is on enabling 2D in retail which will affect the production lines of some trade items if the brand owner sees value in adding dynamic data to the 2D barcode. The 2D barcodes can efficiently carry more data and/or link to web data about the trade item. This opens infinite possibilities for the supply change to leverage. For example, the same QR code (GS1 Digital Link URI) that links consumers to web-based sources of data and enables retail checkout could be used by the supply chain to access trade item master data (e.g., storage temperature, maximum load carrying, etc.) from a smart device. Industry and GS1 are yet to launch a program that standardizes the use of 2Ds throughout the supply chain. Discovering the use cases and readiness of the supply for welcoming 2D barcodes will be some of the first steps.

What are some trends regarding printing and marking that will help to enable the transition to 2D barcodes and GS1 Digital Link?

The printing and marking solution are very dependent on the application. Most brand manufacturers of consumer products might only need their domain name and Global Trade Item Number (GTIN) in a 2D barcode and therefore can add it to their packaging artwork before production.

Other brand manufacturers may want to have more granular data like batch/lot, manufacturing date and serial numbers in addition to their domain name and GTIN. This is known as dynamic data and is usually printed on the production line. Today this data may already be printed as text, but adding the data into a 2D barcode unlocks new opportunities for the brand and the consumer. Initially the brand will work with their printing and coding solution provider to see if the current printing technology and product handling on the line can do the job or if any changes must be made.

Printing 2D barcodes on high-speed production lines and on curved surfaces has challenged the printing and coding industry. Several solution providers have developed solutions for their existing portfolio or delivered new technologies that exceed the fastest line speed. I’m confident that there are now solutions available for the vast majority of brand manufacturers’ 2D barcode printing needs.

To enhance waste prevention and recall preparedness efforts, static, pre-printed barcode information will no longer be adequate for many product categories, such as produce and meat and poultry products. How can manufacturers prepare for this change?

Globally, this has already been happening in the fresh food sector for several years with GS1 Data Bar being scanned in many regions. The migration to 2D puts the same batch/lot and expiration date in a much smaller package. Several retailers that have moved to 2D are seeing scanning efficiency improvements due to the robustness (error correction) of the 2D barcode. The 2D barcode also unlocks other printing technologies due to both its size and matrix structure. In addition to the label and thermal transfer film printers, solutions such as laser, thermal inkjet and others can now be a viable printing alternative. Before the fresh food supplier begins to print 2D barcodes, they should consult with their printing and coding solution provider, local GS1 organization and retailers. Collaboration is key with any change and has been part of GS1 DNA for the last 50 years.

Get started today

If you’re wondering whether your marking systems are ready for the new world of 2D barcodes, contact us at [email protected] for a free expert consultation. In the meantime, download our free infographic detailing the advantage of 2D barcodes.