Making a Name for Yourself: Efficient Wood Marking Solutions Boost Branding

By Kevin Havre

Every builder, contractor, and home renovator consumer is familiar with the sight of wood products with smeared, illegible, or faded marks. But what does that say about the brand?

Just as a wine bottle label tells you about the quality of the wine, wood marking tells your customers about the quality of the timber and your business. So, if your wood marks are inconsistent and low quality, you need to rethink your wood marking solution, and fast.

The quality and durability of your marks directly impact your bottom line. Timber companies that invest in effective marking solutions ensure the traceability and authenticity of their products and creates a lasting impression with customers. So, it’s worth getting your timber marks right.

This post explores the significance of clear marks for branding in the wood industry, emphasizing the importance of legibility and introducing valvejet drop-on-demand technology as a game-changer in achieving precise and durable wood markings.

The power of wood branding

Establishing a strong and recognizable brand in the competitive timber industry is crucial to stand out and develop a devoted customer base. A brand identity should reflect reliability, excellence, and innovation.

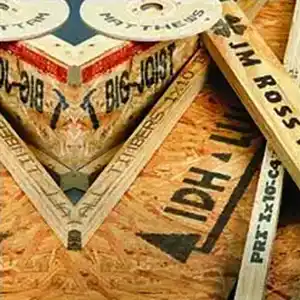

Beyond the quality of the wood itself, clear and legible wood marking plays a pivotal role in enhancing brand identity. Quality branding on your wood products keeps your company’s name front and center with builders, contractors, and home renovators. Whether a logo, company name or a combination of both, a distinct and easily recognizable mark contributes to brand visibility and recognition. This familiarity builds trust and loyalty, influencing purchasing decisions and reinforcing your brand’s image.

Clear and precise wood markings also serve as a testament to the quality and craftsmanship of wood products and to showcase certifications. Customers want to see proof of quality certifications and associate quality marks and with professionalism and attention to detail, creating a positive company perception.

Conversely, the consequences of poor branding are as valid for timber marking as for every other industry. When your logo, trademarks, mill numbers, barcodes, regulatory grade markings, and additional essential information are made with low-quality marks that fade, smear, or are otherwise unreadable, you risk losing your customers’ trust. If your marks are low quality or unreadable, customers may perceive your brand as low quality.

Further, you may have to deal with the cost of reworks and waste, lack of compliance, and reduced efficiency.

What makes a quality brand mark on timber?

A quality brand mark needs to:

- Be easily readable and clear – no smears or fading

- Be durable and able to withstand the elements, such as sun, heat, rain, and forklifts

- Faithfully represent your brand mark

- Be consistent

Choosing the right marking technology for wood

The process of marking on wood and engineered wood products presents some tough challenges, which many marking technologies cannot cope with:

1. Uneven surface texture: Many wood products have an uneven surface texture, which makes it difficult to get a clear, crisp mark when using contact printing methods.

2. Dust and debris: Milling and processing lumber, trusses, and other wood products generate a great deal of wood dust, glue, and residue that can impair the marking process and decrease reliability.

3. Extreme temperatures: Marking equipment needs to withstand extreme temperatures in production facilities that lack heating and cooling.

4. Oddly shaped products: Varying shapes may require highly flexible printing equipment and special mounting considerations.

You need printers that can stand up to these challenges without requiring hours of maintenance – and that doesn’t involve cumbersome contact printing.

Contact printers are not only inefficient and inflexible; they often cause problems with marking, such as smearing, blotching, and inconsistencies, which means marks are difficult to read by consumers and machines. Marks carry less detail when compared to modern valvejet printers. Further, contact printers are also the least flexible method, which slows you down if you have varying timber shapes and sizes, as you have to stop production every time you need to change or update the message.

Another major drawback of contact printing is the higher costs. More ink is used and wasted, and equipment needs to be cleaned and replaced more often due to wear.

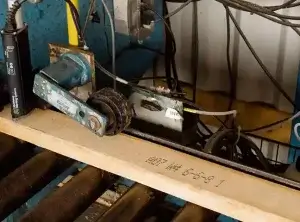

Valvejet printing, on the other hand, doesn’t skip a beat. Printers with automated valve flushing systems and highly reliable printheads provide clearer, crisper marks for timber – as a leading truss manufacturer Stone Truss discovered.

Stone Truss needed help with its legacy system for marking lumber products. It would simply stop working, and even when it did work, the ink would often clog, and the marks would end up so faint the builders couldn’t read them. Staff would still manually write on every piece of lumber – a time-consuming task.

Stone Truss chose Matthews V-Series valvjet printers, MPERIA controllers, and ink supply units. The V-Series features the longest-lasting printheads in the industry, rated for over 9 billion firings per head before tuning is required, meaning less ink, reduced waste, and lower labor costs.

The V-Series printheads offer a choice of 7, 16, or 32 valves with mini, midi, and maxi nozzle options for each, making it the ideal choice for large or small character marking needs. The compact printheads can be easily mounted to reach differently shaped wood products like trusses.

Stone Truss paired a 7-valve mini nozzle printhead with a V-Link module, an MPERIA controller, and a low-pressure ink supply unit. Now, on all lumber Stone Truss runs through the saws, it has easily readable marks that can be seen clearly even on wet wood.

A valvejet drop-on-demand printer system is ideal for marking large characters on wood and lumber.

Gain efficiency through automation and integration

Are you looking to reduce your production costs? Upgrading to modern wood marking technologies like valvejet drop-on-demand inkjet printers provides greater flexibility, reduced costs, and proven reliability even under harsh timber production conditions.

The efficiency of valvejet technology is amplified when integrated into automated production systems. Seamless integration allows for continuous marking, eliminating the need for manual intervention and all the delays this can cause. Therefore, timber companies can achieve a harmonious balance between speed and precision while reducing waste and enhancing overall operational efficiency.

As an EWTA member, Matthews has a long track record of success in the wood products industry and can help solve your toughest wood marking challenges.

Complete the contact form below to receive a free onsite consultation and demo.

About the author

Based in Matthews’ Wilsonville, Oregon office, Kevin Havre is a global product manager for Matthews Marking Systems where he is focused on aligning products with customer needs and driving business strategies for key products and industries. Prior to joining Matthews, he served as a product line manager for Mobile Technologies, Inc. (MTI) with a focus on mobility products. He previously spent more than 10 years at Intel in various product management and strategic planning roles. Additional career stops have included Media Ring, Hewlett Packard and SAVO Electronics. He studied computer science at Oregon State and Washington State universities. In the winter months, you’ll often find him rescuing stranded or injured skiers from the slopes of Oregon’s Mt. Hood where he volunteers as member of the local ski patrol.