Keep pace with a state-of-the-art lumber marking solution

High-speed inkjet marking technology has come a long-way in the last few years. If you’re still using contact printing methods or it’s been a few years since you’ve looked at your print solution, it may be time to evaluate your options. The latest advancements in print technology, ink formulations and system control and integration can pay significant dividends in process efficiency, versatility, speed, reliability and more. Let’s take a look.

Compared to other marking application segments, the wood products industry stands out for having exceptionally harsh, rugged environments along with demanding equipment needs. It’s also face-paced with mills routinely operating at 200 lugs per minute and often looking for more.

Regardless of what marks are being put on lumber – grade, sequence, logos, or barcodes – high-performance mills require marking systems that can keep up. This means print solutions that can withstand the dusty milling environment with zero downtime while still producing quality marks board after board. And compared to contact marking methods such as rollers and labels, digital solutions offer vastly more flexibility to accommodate variable, fast-changing information.

When evaluating marking solutions for your mill, it’s important to remember that not all printers and print technologies are created equal. At a high level, there are two advanced high-speed coding technologies that have a proven track record in the lumber industry: drop-on-demand (DOD) valvejet and thermal inkjet (TIJ).

While continuous inkjet print (CIJ) technology continues to be used for some industrial applications, it is best avoided for lumber applications. For a deeper dive into CIJ limitations, take a look at CIJ vs. DOD/Valvjet and CIJ vs. TIJ blog posts.

Depending on your application requirements, it may make sense to mix and match valvejet and TIJ print technologies for optimum outcomes. Let’s look at how they stack up.

The case for DOD/valvejet

Valvejet printers work by propelling pressurized ink through precisely engineered nozzles toward substrates. The jets are controlled by valves that open just long enough to release a droplet and close. These printers offer flexibility, lowest cost per mark, and unparalleled reliability.

Clear marks on uneven surfaces — Valvejet printheads offer a long-throw distance, which means they create precise, clear marks even on uneven timber surfaces.

Flexible character size — Valvejet hits stride for applications that require both larger and smaller marks. Mark size can range from less than half an inch to several feet tall made by stitching multiple printheads together.

Save on ink, bulk up — Valvejet printers offer the industry’s lowest cost-per-mark, saving you money mark after mark. For the ultimate in convenience, you can obtain ink in bulk supplies such as gallon bottles and drums/totes.

Withstand harsh environments — DOD valvejet printheads, such as the MPERIA V-Series, are impervious to dust and dirt. The electro-mechanical valves only open long enough to fire out a droplet of ink to the substrate, so there’s no chance for dust or particles to make their way to internal components.

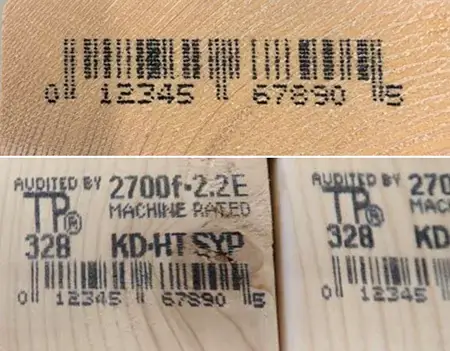

Example barcodes and grade marks created with workhorse MPERIA V-Series valvejet printers.

The case for TIJ

TIJ printers use small, heated chambers within the printhead to create tiny droplets of ink and propel them onto the timber, forming clear and precise marks. They produce high-resolution marks at high speeds with minimal maintenance requirements.

Fast ink changeovers — Cartridge-based printheads can be swapped in seconds, keeping your line running. Each time the cartridge is replaced, it refreshes the printhead.

Lower maintenance burden — TIJ printers require minimal ongoing maintenance for exceptional reliability and efficiency.

High print speeds — TIJ printers deliver crisp, precise marks at speeds of more than 300 lugs per minute to keep up with the flow of lumber in the fastest-paced mills.

High-resolution marking — TIJ offer the industry’s highest resolution, making them ideal for smaller character sizes and for adding tracking or point-of-sale data, such as barcodes and 2D codes on board ends.

Compact size — TIJ printers such as the MPERIA L-Series are an excellent solution for tighter spaces or production processes with bulky materials that are difficult to move, such as lumber.

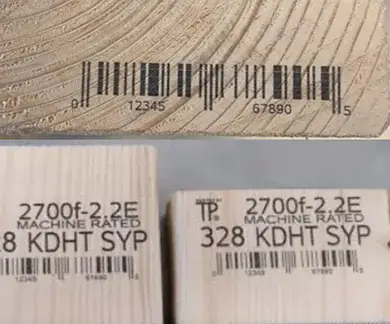

Example barcodes and grade marks created with MPERIA L-Series thermal inkjet printers.

Automation adds speed, flexibility

In today’s fast-paced lumber mills, efficiency means profits. This is where marking automation and full integration with mill control systems becomes indispensable.

When everything works together seamlessly, you can be confident your printers will accurately mark each board without the need for manual intervention. This boosts the efficiency and accuracy of coding while also preventing production interruptions (and the cost involved) for manual message resets, changeovers, or maintenance.

Automation also opens up more advanced marking options for tracking or quality purposes. For example, you could print unique board identifiers such as date and shift of production or a grader’s initials if the board was visually graded.

Achieve top grades in lumber marking

Matthews offers a complete line-up of rugged valvejet and TIJ printers designed to withstand the rigors of wood milling environments while delivering quality marks, versatility and rock-solid reliability. Our easy to use MPERIA controller integrates easily with mill control software and other back office systems and provides full control over print operations through a single interface.

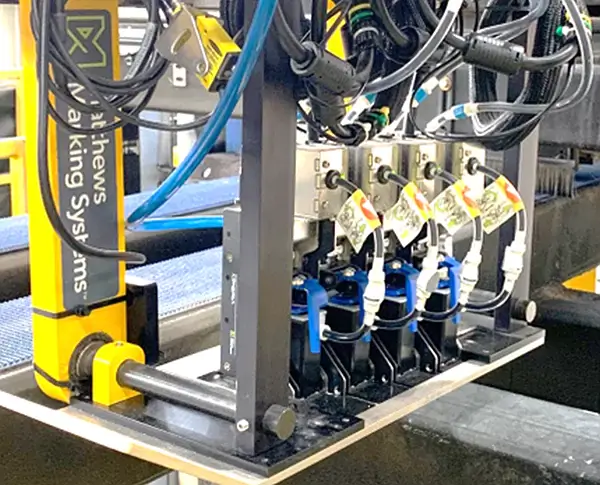

With all the variations in lumber sizes and milling, grading and sorting equipment, off-the shelf stands and brackets alone are rarely adequate.

At Matthews, we have decades of experience supporting industrial marking applications. Our engineering experts can customize our products to fit your specifications – not the other way around. From custom kick brackets and sleds that that move printheads around oddly shaped surfaces to flexible print mounts that raise and lower automatically, our team can create a complete system that works for your needs.

Custom sleds such as this add versatility and help prevent damage to printheads.

Lumber Marking FAQ

What is lumber grading?

Lumber grading involves evaluating wood’s quality based on criteria like strength, appearance, and other characteristics to assign a specific grade. Each grade corresponds to particular uses and applications, so grades must be correct to ensure the lumber is suitable for its intended use. For instance, structural lumber must meet stringent strength criteria for load-bearing purposes.

In the U.S., six associations including the Western Wood Products Association (WWPA), Southern Pine Inspection Bureau (SPIB), Northeastern Lumber Manufacturers Association (NELMA), and National Lumber Grades Authority (NLGA) are responsible for setting and managing lumber grades.

Why is precise lumber grading and marking so important?

Proper grading is vital to ensure lumber is fit for its intended purpose. For example, if a piece of lumber is incorrectly graded, a builder may use it for the wrong application, leading to structural failure and potentially dangerous consequences. Building codes mandate that all lumber used for structural applications bear the stamp of an approved grading or inspection agency. Building inspectors typically won’t approve structures built with ungraded lumber or with missing grade marks as they won’t know the load-bearing capacities of joists and rafters, for example.

Furthermore, accurate lumber grading upholds your business’s reputation by providing suitable products for clients, building your brand with clear logos, and facilitating successful building inspections. Provide clear and precise lumber grading, and your customers (and bottom line) will thank you.

Book your free consultation

Whether you’re looking into inkjet print technology for the first time or want to upgrade your equipment, our experts can help. Contact us for a free consultation by filling out the quick contact form below.