A head-to-head throwdown featuring two of the most popular technologies in industrial marking and coding

Walk into any manufacturing or packaging facility and ask to see the marking and coding equipment. Chances are that you’ll be shown either a continuous inkjet (CIJ) or a valvejet drop-on-demand (DOD) system: two of the most popular marking and coding technologies on the market today.

So how do they compare and which is right for your needs?

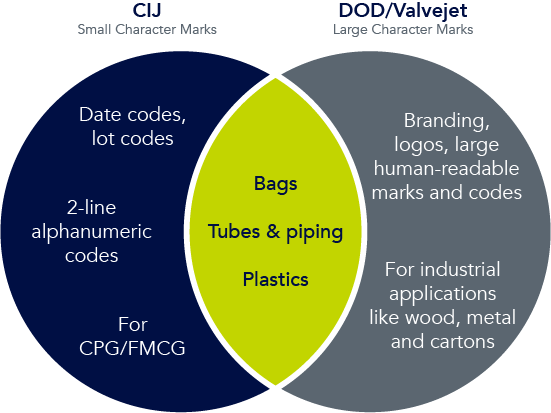

The Venn diagram below shows segments where CIJ and DOD valvejet have gained the most traction over the years based on their respective strengths. But there’s also an overlap where either technology can participate that’s worth exploring.

How do CIJ printers work?

CIJ printers use a high-pressure nozzle to spray a continuous stream of ink droplets from the printhead’s single nozzle.

To form a mark, the stream of ink is first broken into ink droplets through high frequency vibration. A select number of droplets are charged by electrodes and then steered as they pass through deflector plates to form the mark. Uncharged droplets fall into the gutter and back into the ink supply.

Since the ink is exposed to the environment, the ink’s solvent base evaporates continuously and requires the use of makeup fluid. This fluid is needed to make up the difference for the lost solvent and maintain consistent ink viscosity. A typical CIJ will need four bottles of make-up fluid for every bottle of ink.

How do valvejet printers work?

Valvejet printers work by propelling pressurized ink through precisely engineered nozzles toward substrates. The jets are controlled by valves that open just long enough to release a droplet and close. As a result of this design, valvejet printers are very efficient, highly reliable, and minimize the exposure of solvents and other chemicals used in inks to the external environment.

Breaking it down

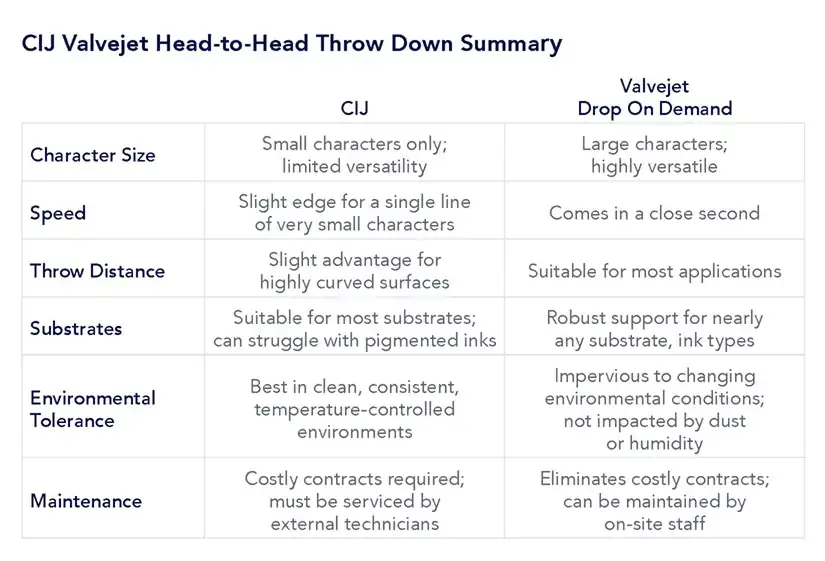

Based on their popularity and broad adoption, both CIJ and valvejet are mature, well-proven technologies for industrial marking and coding. With an understanding of key characteristics, you can make a more informed decision about which technology is right for your application. Let the throw down begin.

Character size

When it comes to placing discrete “use by” or “sell by” date codes on consumer products, CIJ has long been the technology of choice. The smallest font size for these codes is 6-point, or about 1/16th of an inch. The small ink droplets produced by CIJ printers are ideal for such marks. However, as character sizes increase, print quality and/or line speed tends to degrade. For most applications, most CIJ printers are limited to three lines of characters with a total size of around half an inch.

With a much larger droplet size, valvejet hits stride for applications that require larger, easily readable marks. These can range in size from less than half an inch to several feet tall made by stitching multiple printheads together. The size and density of the mark can be easily changed simply by changing the angle of a Matthews Marking Systems’ valvejet printhead when paired with the MPERIA® controller.

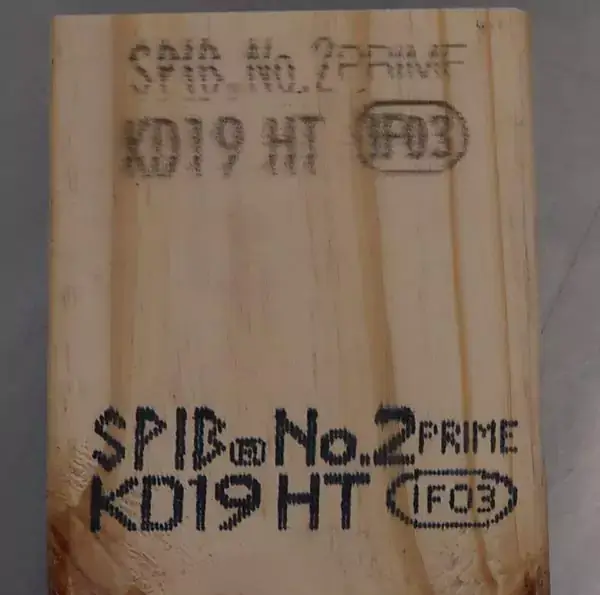

The challenges of using CIJ for larger marks are apparent in the example marks below. A CIJ made the faint top mark after moving the printhead a considerable distance from the wood sample; the valvejet comparison provides much better density and readability.

Winner: Application dependent. CIJ for small characters; valvejet for large characters

This comparison shows the limitation of CIJ for large characters (top mark) compared to valvejet (lower mark).

Throw distance

Factors such as product shape, material handling, and space on the production line dictate the printhead to product distance. Since both CIJ and valvejet have longer throw distances, they can print easily on uneven or irregular surfaces. With its overall longer thrown distance, CIJ is better suited for highly curved surfaces such as bottles and cans. Both work well for surfaces with some curvature such as pipes and tubing.

Winner: CIJ for highly curved surfaces, but otherwise comparable.

Substrates

CIJ and valvejet printers are used for all kinds of products and marking applications, from food products to processed lumber. This is made possible in part through years of research and practical application into ink development. These printers feature large catalogs of fast-drying inks that can adhere to almost any substrate. It’s worth noting that while both print technologies can use dye-based and pigmented inks, CIJ printers have a reputation for running poorly with pigmented inks.

Winner: Valvejet due to its ability to handle pigmented inks

Speed

Production lines run at various speeds and the marking solution needs to keep up. Both CIJ and valvejet printers are up to the task. Depending on the model and supplier, supported speeds are specified at over 700 f/m (210 m/m) for valvejet and over 800 f/m (250 m/m) for higher-end CIJ models when printing single line messages.

Winner: Slight edge for CIJ

Environment tolerance

CIJ printers function best in ideal environments. They like minimal changes in temperature and humidity to do their job. The primary reason for this is that ink viscosity changes when temperature and humidity change. With enough variations, CIJ printers cannot produce consistent ink droplets, resulting in degradation in print quality. Although newer CIJs have attempted to overcome this, it’s still a concern.

Beyond temperature changes, CIJs struggle with particle build-up in dusty environments. Particles of dried ink, dust and other contaminants can accumulate inside CIJ printers and impact performance and print quality. The only way to cope with this is with monitoring and frequent cleaning.

The story is much different for valvejet printers, which thrive in harsh environments. The mechanical valves only open long enough to fire out a droplet of ink to the substrate. As a result, ink viscosity changes aren’t a problem for closed-loop valvejet printheads. And there’s no chance for dust or particles to make their way to internal components. Additionally, the larger droplets are better able to absorb particles with no observable change in print quality. Valvejet printheads can literally be covered in dust debris and still produce high quality marks.

Winner: Valvejet by a significant margin

Maintenance requirements

Given their complexity, CIJ printers are delivered more or less as a black box and as such are fully self-contained. They have many working parts within the main body and fragile parts within the printhead itself. This may simplify the initial set-up but makes onsite repair by the in-house team nearly impossible.

There are only two options to deal with a broken CIJ printer, bring in an expensive technician or send it back to the vendor for repair or replacement. Both options have a negative impact on production. A maintenance contract is a must, and if uptime is important, an idle spare unit or two must be kept on hand.

After approximately five years of operation, CIJ printers start to require a major round of service as pumps and other parts reach the end of their service life. This inevitable decline adds to overall ownership costs and must be factored into budgets.

In contrast, valvejet printers use a modular design. Onsite operations staff can easily maintain and replace individual parts like printheads or pumps just by connecting a few hoses and cables. Service contracts are not needed. Valvejet printers do not need ongoing maintenance other than daily flushing of the valves or at the end of a shift or production run. In the case of the Matthews V-Series, the printheads themselves are capable of more than 9 billion firings before maintenance is required.

Valvejet printers can also make use of large capacity bulk ink supply systems, reducing the need for production staff to monitor and replenish ink (or makeup fluid in the case of CIJ) during operation.

Winner: Valvejet, eliminates the need for costly maintenance contracts

Picking the right tech for your application

In their respective lanes – small character coding for consumer products or large character industrial marks – the choice of CIJ or valvejet is clear.

At the same time, there’s a gray area where either technology could be a possibility. These include bag marking, plastic materials and bottles (think windshield wiper fluid, half-gallon HDPE/PET bottles, etc.), pipes and tubing, and low-resolution case coding and tray packs.

In cases where either technology is a viable option, manufacturers will be able to lower overall costs and improve mark quality by selecting a valvejet-based solutions. What’s more, in some applications currently using CIJ, a larger character mark may be preferable. Even though CIJ continues to be the most popular choice for small character primary coding, valvejet technology should be considered the preferred option whenever possible. If you are uncertain which technology is right for you, it’s worthwhile getting expert advice about your specific needs.

Interested in making a switch or learning more about V-Series and valvejet technology? Give us a call at 1-800-775-7775 or email us at [email protected] to obtain comparison print samples and a free in-depth consultation.