Transform Your Traceability Initiative from Burden to Asset: Three Ways to Make It So

Stating the obvious, your traceability plan probably feels like a huge effort and an exercise in jumping through regulatory hoops. However, savvy companies recognize the tremendous opportunity to get a jump on and outpace the competition. Here are a few suggestions to ensure your traceability program returns the most bang for the buck.

Across every industry, having end-to-end traceability is more important than ever before. Traceability ensures product authenticity and guards against counterfeit packaged goods. It bolsters consumer confidence, and it enables a quicker response to product recall situations.

When you’re in the business of turning nature’s raw materials into a marketable product, it’s absolutely essential to keep tabs on it – from the moment it’s sourced until the finished crate, carton or pallet leaves your plant. And the responsibility for those goods doesn’t stop there – particularly in highly regulated industries like food and beverage, where product quality and integrity are matters of public health.

It’s easy to see why there’s a lot of industry discussion (and hand wringing) around the many nuanced challenges of making traceability work. Producers and manufacturers grapple with accurate tracing in the context of complex supply chains, ever-evolving standards, new regulations and ongoing issues with data integration – both internally and with external suppliers and trading partners. These tactical issues can get messy in a hurry.

Logistics challenges aside, the appeal of traceability shines through and gives a fundamental, sustainable competitive edge to those companies that implement it correctly. Here are three ways to turn your effort into an asset.

1. Use traceability to tap into high-value, premium markets

Fast-rising consumer interest in the origins of the products they buy is driving brands to become more transparent about their sources. This creates an opportunity to take it a step further and tap into the “origins” ethos with marketing that’s focused on sustainable and premium sourcing (and pricing to match).

Witness the popularity of sustainably harvested fish and brands that tout eco-friendly sourcing of wood and paper products or the premium pricing on single-origin gourmet chocolates, farm-direct coffees and small-producer biodynamic wines. While Portlandia’s infamous skit of a couple in a restaurant who ask for minute details about the origins of their chicken dinner may seem a bit extreme, it underscores a very real opportunity for brands to use traceability to their advantage to reach premium buyers and build consumer trust, confidence and brand loyalty. The IBM Institute for Business Value and the NRF found that 71% of consumers are willing to pay a premium for brands that provide traceability.

2. Traceability provides clarity and streamlines operations

Traceability means being able to look at every product through time. That is, you must make sure your products have full, clear, durable and accurate ways to keep track of them, from the finished product on the shelf, back through the entire transportation and supply chain – to every original farmer, supplier and raw material used. This underscores the importance of accurate marking to provide both internal and external traceability. Having serialized identifiers, dates, barcodes or batch codes on every component, product, carton, case and pallet is key.

But just having marks isn’t enough. Traceability requires good data. A mark like a 2D/QR barcode must represent the right information, otherwise you have a garbage in/garbage out problem. According to Packaging Technology Today, errors on labels and packaging are the most common cause of costly food and beverage recalls, for example.

Also, improper marks on pallets – or labels that smear or fall off – can result in your product not making it onto the shelves of your most important retailers. For Pete’s Living Greens (Pete’s), outdated printing equipment that wasn’t integrated with the grower’s data systems made it difficult to maintain both quality and traceability for produce, such as their hydroponically grown butter lettuce. Poorly printed barcodes caused readability issues that resulted in fresh lettuce being held up in quality holds or rejected entirely by major retailers like Walmart and Kroger. And the company recognized that the lack of data integration could be a significant liability should there ever be a need for a recall or other action requiring fast, efficient traceability.

Pete’s solved the issue by switching to a high-quality thermal inkjet (TIJ) marking system and direct carton coding that eliminates labeling-related holds at retailers. It also gives the company more reliable traceability that ensures compliance with FDA requirements, avoids potential fines and instills confidence among the distributors and retailers selling Pete’s products.

Marks done properly, centrally managed, and integrated with back-end data systems yield two very important results: streamlined manufacturing and root cause traceability for problems. This allows producers and manufacturers to determine where raw materials were grown, created, stored, tested, transported, consumed, or disposed of at any point in time. The bottom line: far more efficient identification of issues tied to affected lots or batch numbers. You’re back operating at full capacity that much sooner.

The ability to address issues quickly through traceability not only allows you to track down underlying causes, it also gives you the opportunity to showcase how fast you can respond to your partners, vendors, retailers, and customers, helping to maintain confidence and trust.

3. Traceability helps you stay ahead of regulatory changes and improve your bottom line

As noted earlier, nowhere is traceability more important – or more regulated – than for the food and beverage industry. On November 15, 2022 the FDA finalized its new Food Safety Modernization Act (FSMA) traceability rule. This rule, which will go into effect in January 2023 (or 60 days after publication) gives companies two years to achieve compliance. It requires producers to be able to provide a detailed account of certain food’s origin and movements throughout production, processing and shipping.

While the requirements only apply to those who manufacture, process or hold foods on the Food Traceability List, the requirements were designed to be suitable for all FDA-regulated food products, and the FDA is encouraging voluntary adoption. It’s just a matter of time before more guidelines are adopted (or mandated), both nationally and internationally.

Similar efforts are also being driven within a particular industry such as the Produce Traceability Initiative (PTI) that aims to achieve standardized, tech-enabled traceability across the entire supply chain. By establishing clear guidelines and engaging working groups of farmers, retailers and restaurant chains, PTI hopes to ensure that the six billion cases of produce marketed in the United States each year are traceable – with speed and efficiency – from farm to fork.

The key to making PTI work for companies is streamlining the product marking process with advanced, tech-enabled solutions that are easy to operate and integrate seamlessly with existing systems, from ERP to printers, bar code readers and vision systems in operation throughout the busy production line.

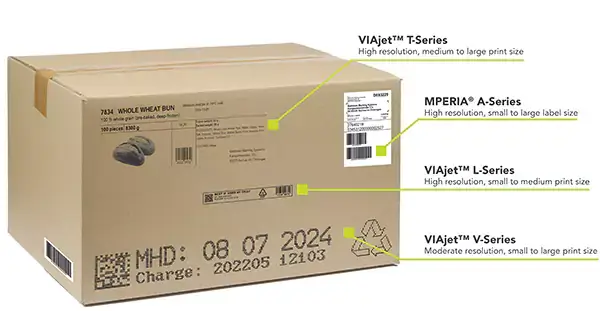

Quality and durability matter. It’s essential to ensure you have high quality marks that will endure throughout packing, shipping and stocking in the store. One way to achieve higher quality marks is through the use of higher resolution printers, such as TIJ printers that can have up to 600 dpi resolution like the L-Series from Matthews. As the graphic below illustrates, it’s important to select the correct technology for your applications. Some technologies that are popular for direct product coding, like continuous inkjet (CIJ), lack sufficient print quality or resolution for many traceability applications. This is not an investment you want to get wrong. But getting it right can also confer the sourcing and premium product advantages we mentioned earlier.

No food is trendier than avocados right now, and Calavo Growers ships 12 million boxes of them annually. The company had embraced PTI labeling standards for its high-volume, 53,000-square-foot, 23-production-line packing facility in Santa Paula but experienced repeated mislabeling issues, including labels falling off altogether. Rather than printing and manual application of bar code labels on the sides of boxes, the company shifted to direct carton coding – ensuring the mark endures throughout the shipping process. Upgrading their marking and coding automation platform also provided Calavo with consolidated control over the marking process, delivering a GTIN barcode readable rate of 100% while increasing efficiency, ensuring accurate traceability and decreasing their costs by 80% compared to their previous system.

Make traceability work for you

Approached strategically with the right technology and partners, traceability becomes far more than a regulatory check box for retailers and customers.

Interest piqued? Get ahold of us for a free demonstration on how Matthews’ MPERIA platform and inkjet print solutions can help you reliably track your products through every step of the supply chain. Gain an edge on the competition while staying compliant with regulations and traceability requirements.