Is It Time to Take Your Marking Operation to the Next Level?

Automation is on the rise in every area of manufacturing, meaning there’s a lot of untapped opportunity to boost production line efficiency and lower costs. The Business Research Company in its Industrial Automation Global Market Report 2023 predicts, “The industrial automation market size is expected to grow to $256.73 billion in 2027 at a CAGR of 7.7%.”

There are plenty of good reasons for this. “Automation improves quality and cuts costs, but the real reason manufacturers automate is ROI. Realizing the projected savings hinges on minimizing implementation costs while maximizing equipment utilization,” according to the Association for Advancing Automation.

In the push toward increasing industrial automation, plant managers and engineers often leave marking and coding systems out of their planning or wait until other processes have been automated. Yet having correct, easily readable marks on products, cartons and pallets is critical to your business – from the manufacturing floor through the entire supply chain – and with the right infrastructure relatively easy to automate. If your marking and coding systems aren’t integrated and automated, you may be missing significant benefits to your bottom line.

Why is marking and coding automation so important?

Automation of the marking function improves marking accuracy and minimizes errors while enabling you to get more from your workforce. In addition, you’ll get real-time visibility into the health of your printers and labelers, new data feeds for your OEE (Overall Equipment Effectiveness) dashboards, and more control and traceability as products flow across your primary, secondary and tertiary packaging lines.

And that’s only the beginning. Let’s dig a little deeper.

Centralized management

A centralized controller, such as MPERIA platform, lets you manage all your printers, labelers, vision systems and coders from one location. This enables significantly faster and more accurate coordination of message updates, changeovers and corresponding data. It also offers significant bottom-line benefits. For example, Calavo Growers was able to pay off its entire investment in marking and coding automation in less than a year.

Faster changeovers

When a product changeover occurs, it is most efficient to change codes at the speed of production from a centralized controller. Automated controllers make this easy – the product codes and setup parameters are preloaded in the system, so when a changeover occurs, the operator simply selects the new product and confirms that the system is set correctly.

Reduction in errors and rework

The more touch points, the more the potential for error. Manufacturing Chemist wrote “the average human makes one mistake for every 300 characters entered. Incorrect information entered on printers by operators results in costly recalls and reworks.” Centralization and automation of the marking function reduces errors and rework in your facility and eliminates potential product holds and recalls in the supply chain due to incorrect codes or labels on packaging and pallets.

Smoother sorting, routing and quality control

A centralized, automated controller can also be used with vision systems and machine readers for code verification and validation. These systems report back to the central system, verifying that codes, text and graphics are correct and readable at every point.

Enhanced supply chain velocity

By validating barcodes and other essential information, you can be sure products will move efficiently through the supply chain, reducing holds and rejections due to incorrect, smeared or otherwise unreadable barcodes.

Support developments in traceability

Traceability regulations are evolving steadily. Marking automation and integration with your ERP and supply chain software help you keep pace. 2D barcodes like QR and data matrix codes are the next generation of coding technology and will bring new levels of complexity that must be managed efficiently.

Better visibility in the back office

Because automated controllers are also data platforms, they can integrate seamlessly with your ERP and other business software, supplying essential marking and coding data for inventory management, OEE efforts and business decision-making.

What does an automated marking and coding system look like?

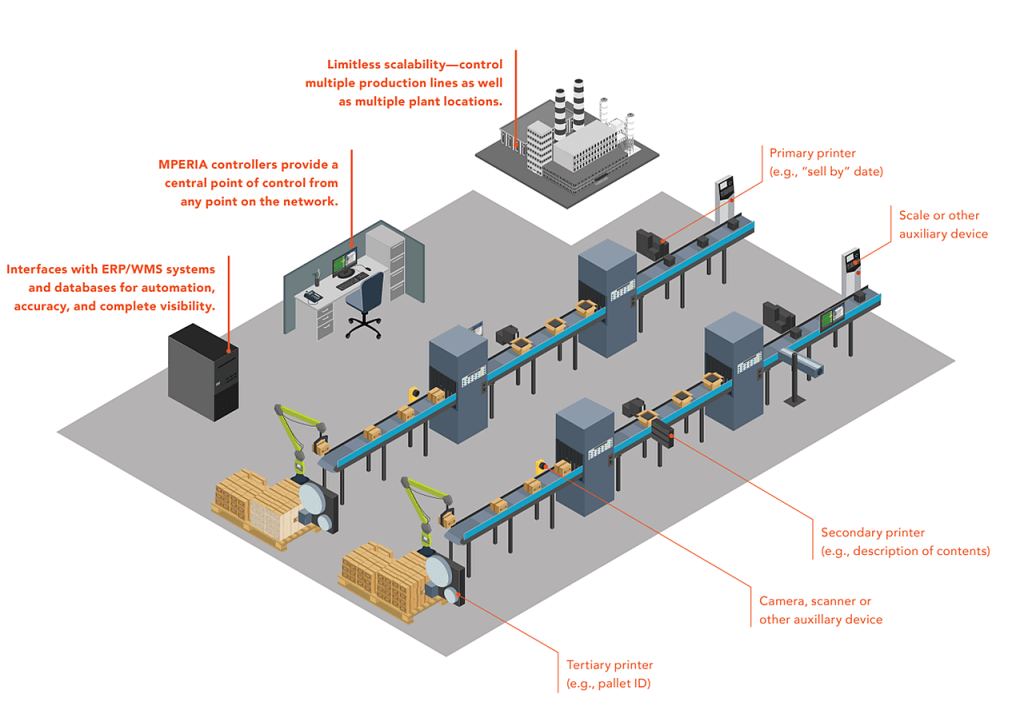

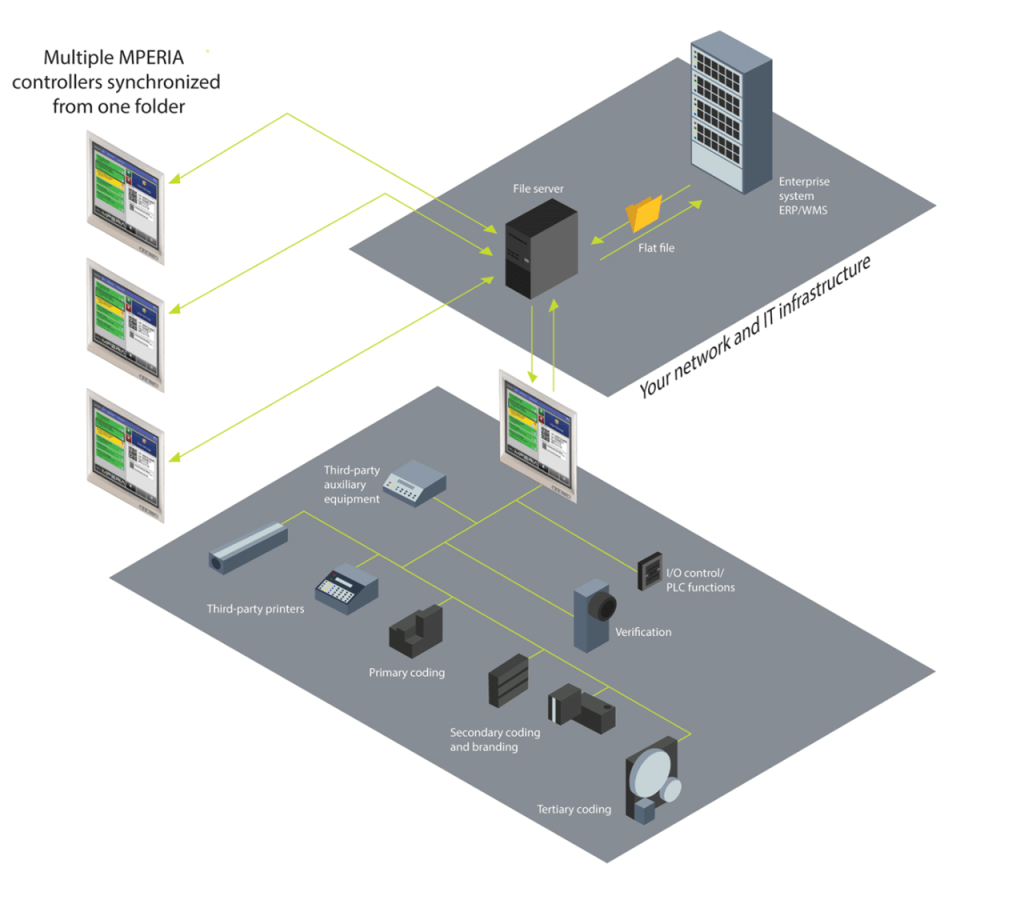

As an example, let’s look at how the MPERIA universal marking and coding automation platform works.

MPERIA delivers centralized control of your marking, primary, secondary, and tertiary. You can control one printhead or every printer on your production and packaging lines, and line operators only need to be trained on one system to start jobs, manage changeovers, and resolve issues faster.

Use every advantage of automating your marking with MPERIA by controlling your printing equipment as well as vision systems, ERP/WMS system integration, and backend databases.

Get started today with marking and coding automation

If you’re still using manual processes to manage your marking and coding, moving to an automated solutions should be high on your list of priorities. Automating marking and coding with a controller like MPERIA creates economies of scale that will measurably improve your bottom line. And because it seamlessly integrates with virtually any coding equipment, data file, or enterprise system, you don’t need to re-engineer existing data systems or change current workflows to start reaping the benefits today. Flexible architecture and a library of standard plugin drivers—along with the use of common communication protocols—keeps integration costs down and makes equipment upgrades easy.

We’d love to tell you more or show you our products in action. Contact us anytime using the form below.