What capabilities should you look for in a print controller?

Imagine having an automated controller that lets you control all your coding and marking from one place. It improves the accuracy and consistency, speeds up changeovers, and integrates with other printers and equipment on your line.

And the best bit? You don’t have to be a tech wizard to know how to use it.

If that sounds too good to be true, it’s not – you simply need to look for a marking and coding controller with specific features and functions.

Let’s break them down:

1. Intuitive user interface

This is an interface that works exactly as the user expects it to. In today’s world, that means a touch-based interface that functions similarly to a smartphone or tablet. For example, when a user sees a button or icon, they assume it will perform a specific action when they tap that button. We don’t have to think about it works; we know how it works. And we get helpful guides and pop-ups to guide us through more complex tasks.

When it comes to marking and coding controllers, this usability is essential. It means any operator can quickly learn how to create and edit messages and perform other tasks.

The main benefit of a user-friendly interface is that it increases productivity. When your team can easily find and use the features they need, they can focus more on their work and less on figuring out how to use the controller. Your team can select and verify messages in seconds, reducing marking errors and saving hours of labor – not to mention decreasing downtime and reduced waste due to mismarked products.

Additionally, a user-friendly touchscreen-based interface helps with training and onboarding. When the system is intuitive, employees can quickly learn how to use it, reducing the need for extensive training for operators and maintenance staff.

2. Support for multiple technologies

For optimum versatility and flexibility, a print controller that can support multiple print technologies can be a game changer. If you have production lines with various print and labeling technologies, or you want to adopt new technology, you need a controller that can accommodate whatever you throw at it. If one printer is out of the loop, you’ll lose time on manual updates and changeovers and increase potential for errors.

For larger operations, centralized control and automation holds the key to improved efficiency. When you centralize coding control across your all production lines from product to pallet, you can identify and remove packaging and marking bottlenecks.

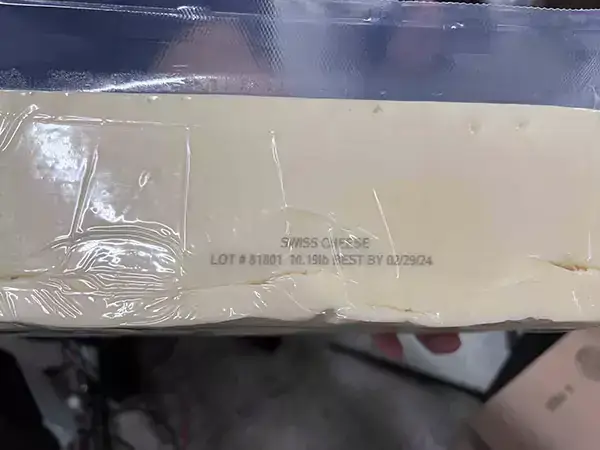

This flexibility makes it easy to craft the exact solution you need for your operation. One company in the food and beverage industry, Fairview Swiss cheese, uses MPERIA to integrate a thermal ink jet printer with a scale. The weight data is feed directly to the controller and printed in real time as product moves down the line.

Thanks to integration with a digital scale, Fairview Swiss cheese is able to automatically print precise weight data, along with date and lot codes, on each block of cheese.

3. Open source platform

There’s nothing more frustrating than finding a technology with everything you need, only to discover that it can’t be integrated into your existing environment without investing in even more software and hardware.

Whether you have scales, scanners, or barcode validation systems, every application has different integration requirements. That’s why an open source platform is a major bonus. For example, the MPERIA controller is built on flexible open-source architecture and includes a library of standard plugin drivers and common communication protocols to make equipment integration and upgrades easy – no need to invest in complex middleware.

And because it seamlessly integrates with virtually any coding equipment, data file, or enterprise system, you don’t need to re-engineer existing data systems or change current workflows. The platform easily scales to control dozens of printers and other devices across multiple lines with nearly unlimited message creation capabilities.

When business systems need to be integrated, it also automates data flow from those systems.

This opens up a world of possibilities. In one use case, EstiFrame Technologies needed to upgrade the printing capabilities of its EasyFrame saw. Customers use EasyFrame to cut lumber to correct sizes for a job or project and to automatically print the identification marks needed for construction on each piece.

For this to work as intended, data needed to flow from the EasyFrame’s controller to the printers. This ended up being a simple proposition thanks to Matthews’ MPERIA OEM controller driving MPERIA T-Series high-resolution piezo inkjet printers. Tapping into the open source MPERIA platform, EstiFrame used simple XML scripts to establish communication and ensure data accuracy when printing marks on lumber.

Integration was so easy that the EstiFrame team got the first demo unit up and running in one day. “It’s an amazing print controller — very streamlined, very sensible,” said co-founder and product manager Coby Gifford. “What we really liked about it was the fact that you can literally manipulate the XML on the controller itself. We were really, really impressed.”

4. Robust construction

Every technology you bring into your production facility must be built for the long haul. You need to know that it can withstand dirt, dust, grime, extreme temperatures, and many other damage threats, and isn’t going to fall apart when the going gets tough. Look for a controller, like MPERIA, with available models for use in harsh industrial environments including a top of the line model with full IP65 rated protection.

MPERIA ticks all the boxes

Don’t let outdated, inflexible marking systems hold your business back. The MPERIA Controller is the pinnacle of automated marking and coding efficiency.

With its user-friendly interface, automation capabilities, and seamless integration, the MPERIA controller will revolutionize your product, case, or pallet marking processes. With minimal training required, it empowers operators to switch messages in seconds, improve mark quality, and centralize coding control across production lines.

It effortlessly integrates into existing environments by eliminating the need for custom software or server hardware, leveraging current enterprise systems and legacy equipment. With flexibility and scalability, MPERIA will grow alongside the evolving needs of your production line.

Get a free demo

Time to upgrade your marking and coding solution? Request a demo to try the MPERIA Controller. Or chat with our team to find out more. Contact us on 800.775.7775 or fill out the quick form below.