Why case coding flexibility is key to complying with big box retailer guidelines

If you’re considering taking the plunge with major retailers, you need to play by their rules.

Getting onto the shelves of a major retailer is a game-changer for any manufacturer, but it also comes with many responsibilities. One of these responsibilities is case marking and coding. The key to success, as we discuss in this post, is to have a flexible and integrated marking system that can adapt to a shifting landscape.

Retailers have strict carton marking requirements and these can differ from retailer to retailer . Working out how to comply with multiple retailer guidelines can be a constant headache for CPG manufacturers, and the fate of your contract depends on getting it right. Additionally, requirements change and evolve over time, putting even more pressure on your coding processes.

So, how do you comply with major retailer carton marking requirements without tearing your hair out?

Let’s dive in.

Know the rules

Before you can play by the rules, you need to know them – and they aren’t always straightforward.

Big-box retailers’ carton marking and labeling requirements are renowned for being strict and unyielding. But it’s for a good reason – retailers are all about driving efficiencies and profitability. Every rule is designed to make it faster and easier to get products onto shelves and into customers’ hands.

Suppose you’re already supplying to one retailer and considering supplying to another. In that case, you’ll have realized by now that it’s not as easy as keeping the same carton labeling and coding for both. Certain common requirements are used by some retailers, including GS1 standards. However, there’s no one set of coding and labeling rules for all consumer product goods.

From how many labels or prints/codes are required to what goes on the labels or marks to where they should be applied, you need to know precisely what each retailer wants.

To demonstrate how detailed the requirements are, here’s a snippet of Walmart’s and Kroger’s requirements for case marking:

Walmart

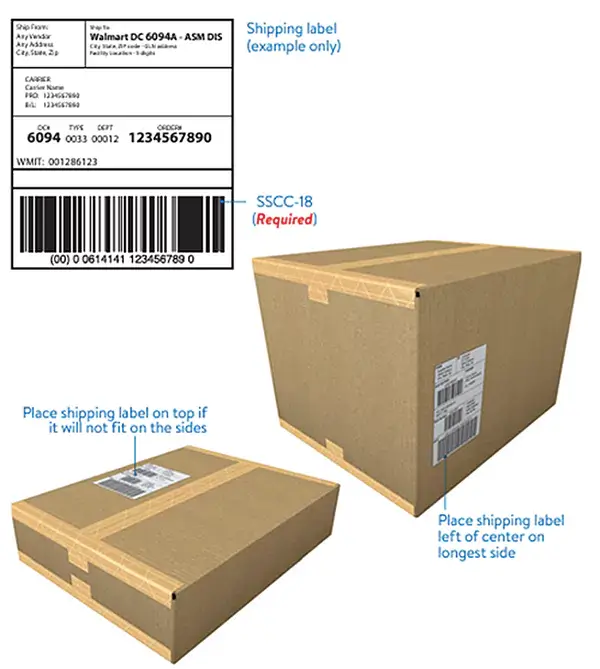

Walmart’s Supply Chain Standards for Secondary Packaging guide runs over several hundred pages with multiple pages of detailed instructions for case marking and labeling. Case marking should not be confused with shipping labels – case markings identify all information specific to the shipping case, while the shipping label identifies information particular to the PO.

Walmart’s general case marking guidelines require that at least two sides (one being the longest side) of all standard shipping cases contain the required information:

- 14-digit GTIN (ITF-14 UPC A/E format) barcode printed in black ink only

- Must follow ANSI/GSI print standards to ensure scanability

- Minimum code size ¾” H x 3” L

- Print code or place label at least ¾” from edge of the case side wall and 1.25″ from the bottom of the case

Additional data to include where applicable:

- Brand/sub-brand and item description

- Supplier stock number

- Walmart item number required for assortments, shoes, and apparel

- Color, size, or style

- Multiple flavor descriptions or unique UPCs cannot be printed on the case.

- Lot code/best if used by date requires a minimum font size of 1/2″/48pt and a preferred date format of MM/DD/YYYY (on one side only).

- Country of origin (COO) is required for all produce and recommended for all other items.

Example of labeling placement requirements from Walmart’s Supply Chain Standards guide for secondary packaging.

Kroger

Unlike Walmart, Kroger requires all cartons to display only one scannable barcode each:

- All barcodes must be in scannable condition upon receipt

- Place on the long side or top

- Minimum size 2.5” x 2”

- Barcodes must be printed on label stock unless an exception is approved

- A 14-digit case GTIN barcode may be printed directly onto the shipping carton instead of using a barcode sticker.

- Size to be proportional to the shipping marks printed on two sides of the carton.

- Suppliers are to self-check the scanning and the strength of the cartons during their final QC inspection to avoid Kroger’s re-sticker fee chargeback if the barcode fails.

Avoid retailer chargebacks

If you want a successful relationship with big box retailers, ensuring cartons are always marked and labeled precisely is critical. Retailers are quick to issue fees and chargebacks if you don’t meet their requirements. If you make a mistake, you could see rejected deliveries, delays, extra charges, and rework to get your products on store shelves – all of which eats into your bottom line.

For example, Costco conducts random performance compliance audits to confirm that packaging meets specifications. If the packaging is non-compliant, the item may not be stocked or will be subject to a 2% chargeback to reimburse the retailer’s extra operational and handling costs as a result. Also, Costco will bring no new products into the system unless they comply with its packaging requirements, so if you want to get on the shelves, you need to be compliant from the get-go.

Get flexible with case marking

The key to success with big-box retailers is to have flexibility and precision in your inkjet marking and labeling equipment. There’s no “one size fits all.”

Ideally, you’ll want to ensure you have the best solution for your particular circumstances. Depending on how many retailers you are dealing with, you may need a flexible solution to address varying and conflicting requirements.

Although multiple marking solutions exist, the top three are thermal inkjet, piezo inkjet, and automated print-and-apply labeling. Deciding which technology depends on your requirements; however, it’s important to consider more than just the marking or labeling technology.

If direct carton/tray pack marking is your best option, high-resolution inkjet printers such as L-Series thermal inkjet (TIJ) printers and T-Series piezo inkjet (PIJ) devices, can produce high-quality, durable marks on corrugated and other materials that scan consistently.

If direct marking isn’t an option, automated print and apply is a great alternative. The MPERIA A-Series offers the speed, ease-of-use and low-maintenance needed across packaging production lines. Offering multiple applicators and configurations, the A-Series ensures accurate and reliable labeling on every carton.

If your requirements span both situations, the MPERIA controller is the only universal marking and coding automation platform on the market that works with virtually any hardware or software. It can control multiple devices and technologies through a single interface.

Book your free consultation.

Whether you’re looking into becoming a big-box supplier for the first time or are adding another retailer to your books, working out how to meet carton marking requirements can be confusing. The first step to compliance is to contact us for a free consultation by filling out the quick contact form below.