Fight back against counterfeiters with cost-effective laser coding

By Gary Bolton

- Counterfeiting is a global problem and it’s vital for manufacturers to implement counter measures.

- Using laser marking machines to place unique, permanent codes on products and packages is a simple and effective way to fight back.

- Manufacturers use both overt and discreet laser marking strategies to thwart counterfeiters.

According to the US Chamber of Commerce, the impact of counterfeit goods on the global economy can run more than $500 billion a year. Year after year, businesses are losing a significant amount of their profit to counterfeited goods, with the Organization for Economic Co-operation and Development (OECD) reporting that counterfeiting accounts for 3.3% of all global trade.

In addition to wreaking havoc on markets, fake drugs, automotive parts, electronics, foods and beverages including wine and spirits, tobacco and other consumer packaged goods can have serious impacts on the health and safety of everyday consumers and entire communities.

The global impact of counterfeit goods on the economy exceeds $500 billion annually. An estimated 3.3% of the goods on container ships like this are counterfeit.

With laser marking comes great power

With counterfeiters becoming more and more aggressive with their methods, manufacturers can ill afford to sit back and hope they can get lucky and fly under the radar; some level of anti-counterfeiting measures is a must.

While there are plenty of “exotic” anti-counterfeiting technologies such as 3D codes and invisible inks, one of the easiest ways to fight back is by using laser printing machines to engrave permanent, hard-to-replicate codes and symbols directly on products and packaging.

Compared to the alternatives, laser marking is far easier to implement as just another step in the manufacturing process. What’s more, if you’re already marking products with date codes or batch information using continuous inkjet (CIJ) printers, it’s simple to switch over to a laser marking solution. You’ll get higher quality marks, eliminate consumable costs and enjoy minimal maintenance requirements while drastically improving counterfeit protection. And you’ll be more sustainable.

Laser coding also gains high marks (pun intended) as an anti-counterfeiting technology because you can engrave marks on a wide variety of substrates including glass, plastic, coated metals and multi-layer foils, labels, and more – all at production line speeds.

Why does mark permanence matter?

Inauthentic goods often are made from low-quality or fake materials, but often look genuine. However, their lack of a mark can prove they are not the real deal. Permanent marking can also help prevent counterfeiting by making it impossible for counterfeiters to refill or reuse packaging with a different product or a lower quality product. Further, permanent marking can help you avoid damaging product recalls, by ensuring you can identify and isolate defective or contaminated products.

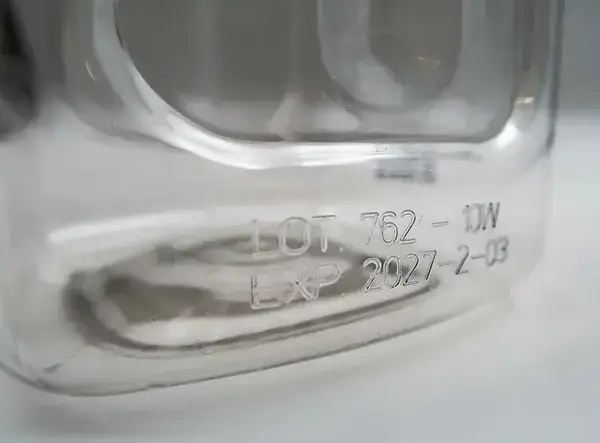

Permanent laser marks make it difficult for counterfeiters to reuse or refill packaging.

What types of anti-counterfeiting marks are used?

Manufacturers can improve their protection against counterfeiting with both overt and discreet laser marking strategies.

For overt marking, the laser is used to create visible and recognizable indelible marks on the product or packaging, such as logos, names, or symbols. Overt marking can help consumers identify the original product and distinguish it from fake ones. Overt marking can also deter counterfeiters from copying marks, as they are difficult to reproduce with the same quality and accuracy as with laser coding. Overt marking can also enhance the brand image and value of the product, as it shows the quality and reliability of the manufacturer.

As the name implies, invisible or discreet marks can be “hidden” within images or contained within 2D codes. The latter can help consumers verify the authenticity of a product by scanning the code with a smartphone and accessing product information online. Discreet marking also deters counterfeiters from tampering with products or packaging as the marks are hard to detect or remove.

Tried and true: laser coding for the win

The sad reality is that counterfeiting will likely never disappear and will continue to create obstacles for manufacturers, distributors, retailers and consumers. You can liken it to a game of whack a mole – every time you knock down one counterfeiter, another one pops up.

The silver lining is that permanent laser coding has emerged as one of the best tools in the arsenal for fighting back because of its efficiency and versatility. If you’re concerned about the ever-present threat of counterfeiting and are looking for a way to protect yourself, complete the form below and one of our experts will be in touch to schedule a consultation.