Bottles & Cans

Get flexibility, accuracy, and quality with low-maintenance solutions for marking at high speeds.

Marking and Coding Solutions for the Beverage Industry

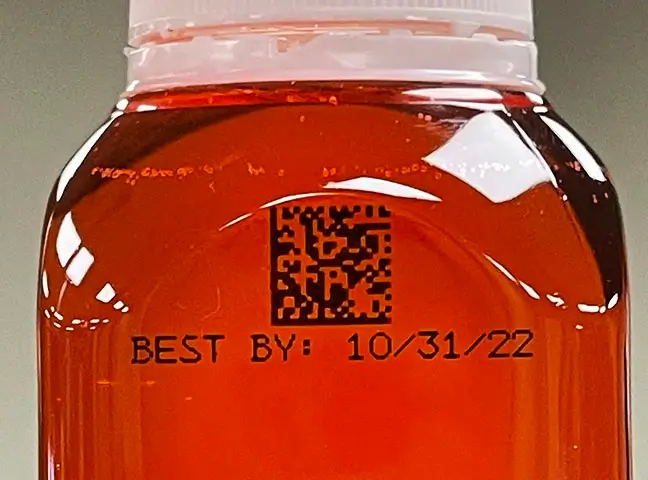

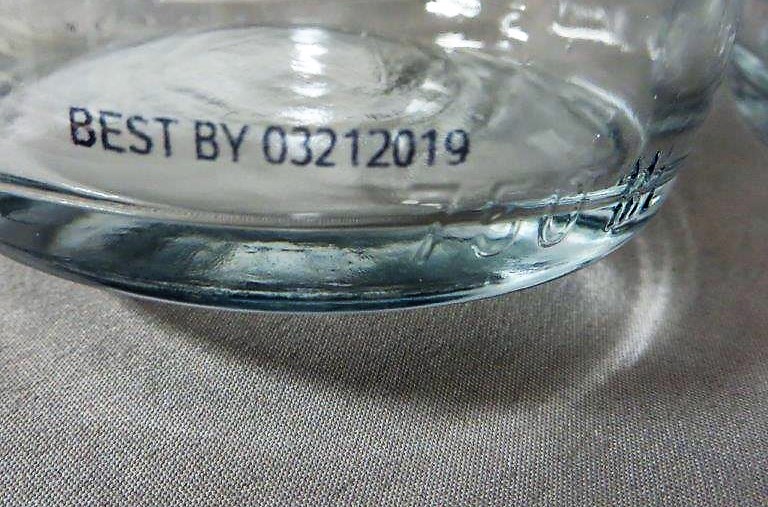

The only thing more important than easy to read and accurate “best by” expiry date, batch, and lot codes is making sure your line doesn’t stop. We can help you with both. Our laser coding machines maximize uptime by producing vector-quality codes at high speeds and help you meet the high production demands of the beverage industry without sacrificing quality.

Substrates and applications include:

- Glass bottles

- Plastic bottles

- Aluminum cans

- Barcoding

- Lot, batch, and ID coding

- Branding

1

2

Recommended Products

Resources

Case Study

When a major manufacturer of soft drinks, syrups and beverage concentrates needed new laser marking systems and universal printer control across their facility’s three production lines, they turned to Matthews Marking Systems.

Laser marking for bottles case study

Case Study

To meet a new regulation requiring “best before” date coding on their beverages, a small bottler needed a new, automated marking system.

Beverage "best before" date case study