Inkjet Printing 101: How TIJ and PIJ Stack Up Against Each Other

When printing on secondary packaging – think corrugated cartons and cases for shipping multiple finished products to retailers — there are three main types of inkjet print head technologies to consider for best results: thermal ink jet (TIJ), piezoelectric inkjet (PIJ) and valve-jet.

For coding and marking of secondary packaging, making the right choice in print technologies can ensure you’re able to get the marks you need to meet regulatory requirements, represent your brand in the best way possible, and get the maximum value from your investment in a marking solution.

As we discussed in our CIJ vs. TIJ post comparing marking technologies, the most popular technology for high-volume primary coding applications, i.e. direct marking on products, is continuous inkjet (CIJ). However, particularly for marks that require higher resolution or larger sized characters, TIJ is emerging as a viable alternative to CIJ for many primary product coding applications.

Unlike CIJ which is mostly used for primary coding applications, thermal inkjet technology also has a strong play in case and carton marking applications, as does PIJ. In this post, we look at how TIJ – the veritable jack of all trades – stacks up to PIJ technology, which has long been an excellent solution for these types of applications, including printing images and branding. We’ll be taking a closer look at valve-jet technology and its pros and cons for secondary marking in an upcoming post.

A brief look under the hood of TIJ and PIJ

Compared to CIJ printers, which use a pressurized nozzle to spray a continuous stream of ink drops from the tank to the cartridge, TIJ print heads and PIJ use heat or electrical currents (respectively) to push ink out of the nozzles when it’s required. Like valve-jet printers, this style of print technology is broadly known as drop-on-demand or DOD since the ink droplets are produced on demand.

That said, although TIJ and PIJ share similarities, there are some key differences in how each of the systems work.

TIJ print heads release ink into small chambers of the ink cartridge and then quickly increase the heat inside those chambers. This creates vapor bubbles in each of the chambers. The bubbles create pressure, which ultimately pushes the ink out of the nozzle. The heating elements then rapidly cool, “popping” the bubble, and the process begins again.

On the other hand, PIJ printers use electrical charges and vibrations to send droplets of ink onto a substrate. The electrical charge “excites” a crystal or ceramic element in the printhead which oscillates ink into droplets before they’re fired through a nozzle.

How does TIJ compare to PIJ?

Understanding how TIJ and PIJ differ can help you make the right decisions for your production lines. Below we have put together a list of pros and cons to help guide your decision making. The first provides advantages and disadvantages of TIJ, while the second part focuses on PIJ.

TIJ Advantages

- Best resolution: TIJ has the highest resolution with up to 600 DPI.

- Nozzles per inch: Because TIJ print heads can have up to 1,200 nozzles per inch, more ink can be ejected in one pass than with other technologies — resulting in a better-quality mark.

- Increased output: Because more drops can be ejected at a time, TIJ allows for a wider variety of color and shading in a single pass.

- Cost effective: TIJ cartridges are easily swapped out when the ink is used up, and include the print head so there is no need for periodic external maintenance to maintain print quality. In addition, there is very little training needed to run and maintain a TIJ printer.

- Small footprint: TIJ printers are small, lightweight, and portable. This makes them a great option for both large scale and small-scale operations, or any time when space is at a premium on the production line.

- Reduced power consumption: TIJ print heads require less power to operate than other types of printers, which can have an impact on both sustainability and helps lower costs.

- Less VOC emission: Self-contained TIJ ink cartridges deliver only the ink necessary for printing. This means fewer volatile organic compounds (VOCs) are released into the environment, making TIJs a safe and healthy choice for employees.

TIJ technology is ideal for applications that require large human-readable characters and fine detail, such as 1D barcodes.

TIJ Disadvantages

- Throw distance: TIJ has a fairly short throw distance, which means that for an accurate mark the product must be within about ¼” (6.4 mm) of the printer. In addition, the product must be moving in a smooth manner. That said, TIJ printers with longer throw distances are now starting to come to market, which could improve TIJ’s viability for many primary packaging applications.

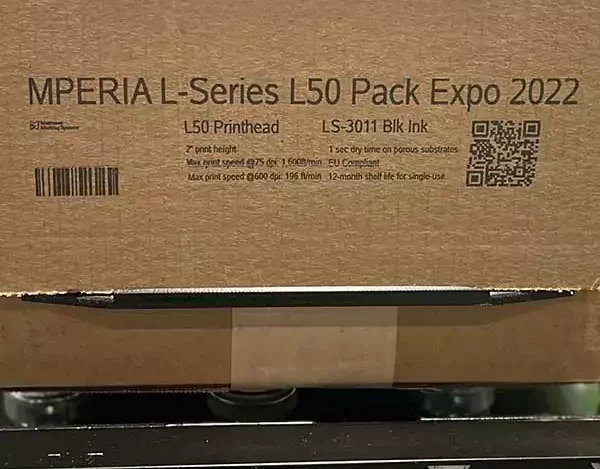

- Print height: Each TIJ print head has a lower print height compared PIJ technology (typically 25mm). This isn’t a major disadvantage since multiple print heads can be rigidly mounted together to allow 2” print heights, such as the case with the Matthews L50 TIJ print head shown below.

- Less choice: Because of the use of heat with a thermal printer, there can be fewer options for ink type and color. TIJ printers may require specialized inks for certain substrates, which can add to the cost of use.

- More frequent replacements: Because of the high heat that is being used, TIJ print heads need to be replaced more frequently then PIJ print heads. However, as noted above, this is part of the cartridge replacement process and is a fundamental part of how TIJ print heads are designed.

- Slower speed: Compared to CIJ printers, TIJ printers may not have the speed needed for fast moving primary marking applications. However, print speed is superior to PIJ.

Multiple TIJ print heads operating as a single unit can be mounted on the same plate to support larger print sizes.

PIJ Advantages

-

- High resolution: While not to the same standard of TIJ’s resolution, PIJ printers are capable of delivering high quality marks with up to 300 DPI.

- Print height: PIJ technology allows for better native print height, with 2” and 4” (50mm or 100mm) options typically available. In addition, nested piezo actuators can be joined in support applications that require larger marks.

- Throw distance: PIJ has a longer throw distance of up to ½” (12mm) compared to TIJ, which may provide greater flexibility for some secondary and industrial applications.

- Droplet size: PIJs can produce a variety of extremely precise droplet sizes, which can support image quality and lower cost per mark.

- Specialized inks: PIJ is compatible with specialized inks that can be used on porous surfaces.

- Minimal maintenance required: While ink may need to be purged on occasion, there is little maintenance needed beyond that, especially with automated cleaning systems in place. Like TIJ, there is very little training needed to run and maintain a PIJ printer, and they tend to last a long time.

- Reduced power consumption: Similar to TIJs, PIJ print heads require less power to operate than some other types of printers, which can have an impact on both sustainability and lower costs.

- Less VOC emission: PIJ printers are available with VOC-free (oil-based) inks, making PIJs a safe and healthy choice for employees.

PIJ Disadvantages

- Fewer nozzles and print heads per printer: With 100-300 nozzles per inch, the quality of the mark will be less than that of a TIJ printer.

- Sensitivity: PIJ may be more susceptible to dust, temperature and humidity than other printers. This could cause issues with the print head and may impact ink output.

- Cost: PIJ typically has higher upfront costs than TIJ.

- Only works on porous substrates: PIJs are only suitable for marking absorbent materials, limiting it carton marking applications and industrial applications involving porous materials such as wood products.

- Slower speed: PIJ printers lack the speed needed for fast moving primary marking applications and lag behind TIJ.

PIJ printers are ideal for label replacement applications on porous materials.

Deciding Between TIJ and PIJ

While we cannot give definitive advice on which technology is better for you without seeing your production line, we can give some guidance on where TIJ or PIJ may work best. One note for both: if you need high speed or a longer throw distance for primary marking of consumer goods, you’ll want to look at CIJ or laser coding options. However, both TIJ and PIJ technologies, as well as valve-jet printers, are ideal for most direct-to-product marking and coding in industrial settings and all direct-to-carton printing applications, eliminating the need for labels. And both technologies provide higher resolution, create less mess and are generally far more user/operator friendly than CIJ.

- TIJ: Works best for products that don’t require large scale marking with taller heights. In addition, TIJ will give you the best resolution for your marks, hands down. Some of the best use cases for TIJ are single- and multi-line text, , fixed and variable data and retail branding and traceability. In addition, due to its low start-up and maintenance costs, along with the small footprint, TIJ printers are a great solution for small volume producers and production lines.

- PIJ: If you’re using specialized inks or need larger character height, PIJ is the better option. Similarly, PIJ is the best pick if you need a printer that can handle a variety of ink types and/or need larger high-quality images. For this technology, the best use cases are secondary packaging and direct carton marking where barcode readability is critical, primary marking of wood products or other porous substrates and large graphic marking at up to 80-in. as shown below. Because of the higher start-up costs, PIJ may not be the best bet for small volume producers and production lines. As we’ll be discussing in a future post, valve-jet printers such as the Matthews V-Series offer superior performance and reliability for industrial and carton coding applications that don’t require high resolution.

PIJ printers can be stitched together to produce very large marks for branding and other applications.

One Controller for All Your Print Technologies

Fortunately, with Matthews Marking System’s MPERIA platform, you don’t need to choose between TIJ or PIJ, as it can support both print technologies and more from one controller. This means you can automate and centralize your coding and messaging through one interface, no matter which print technology you are using. So, whether you want the resolution and high speed of the MPERIA® L-Series thermal inkjet printers or the versatility and exceptional color reproduction and graphic printing of the MPERIA VIAjet T-Series piezo inkjet printers, we’ve got you covered!

Interested in a demo of how MPERIA can make your TIJ and PIJ printers work in harmony to deliver superior results? Give us a call at 1-800-775-7775 or email us at [email protected].