Sierra Aluminum upgrades from CIJ to DOD to achieve 50% improved efficiency, lower costs, and anticipated one-year ROI.

After experiencing consistent, production-halting performance issues with their existing CIJ printing solution, Sierra Aluminum tackled their challenge by implementing Matthews Marking Systems’ VIAjet™ V-Series DOD Inkjet Printer with the MPERIA® automation platform.

Summary

Sierra Aluminum is an aluminum extrusion mill that also provides a range of value-added services (anodizing, fabrication, and more). The company’s CIJ marking equipment regularly caused production line stoppage, putting their schedule at risk. Known for quality, expertise, and timeliness; failing to deliver on time to customers was unacceptable. The team at Sierra Aluminum replaced their existing printing solution with Matthews Marking Systems’ VIAjet™ V-Series DOD inkjet printer with the MPERIA® automation platform. Implementing this advanced system allowed the company to quickly achieve:

+ 50% greater line efficiency

+ Centralized control of print production

+ Substantially lower maintenance costs

+ Decreased ink costs

Installed and commissioned in only one day, the new solution didn’t require any modifications to the existing production line. Overall, Sierra Aluminum anticipates seeing a full return on their investment within one year.

The Challenge

Sierra’s existing CIJ solution was not sustainable. Javier Espinosa, the Plant Manager for the Riverside facility, needed a dependable, industrial-grade marking solution that could:

+ Excel in the mill’s harsh environment,

+ Reliably perform with minimal maintenance, and

+ Produce a quality mark consistent with Sierra Aluminum’s brand reputation.

“The system required a lot of ongoing maintenance, and regularly drove up our downtime costs,” says Espinosa. “There were times when we couldn’t fulfill customer orders because the printers were not working.” At times, the team was forced to move their one functional CIJ printer between facilities in order to maintain production flow. “We couldn’t afford to consistently delay customer orders due to printer malfunctions,” Espinosa says. “Those delays hurt our customer relationships and were damaging to our brand.”

The Solution

Matthews Marking Systems’ V-Series DOD inkjet printer with the MPERIA automation platform easily fulfilled Sierra Aluminum’s requirements, ensuring they could confidently meet operational goals while delivering customer satisfaction.

Outstanding Reliability, Durability, and Efficiency

The solution is durable enough to withstand even the most challenging industrial environments; provides optimal efficiency with the longest-life printheads in the industry (over 9 billion firings); and reliably prints crisp, clear marks with precise placement and timing. Routine cleaning and maintenance is greatly simplified with the flushing valve systems in the V-Series. An advanced printhead nozzle design, featuring exclusive micro-valve ink circulation technology, dramatically lowers ink consumption without compromising print quality. The combination of reliability, durability and efficiency allowed Sierra Aluminum to maintain maximum line productivity with minimal maintenance and almost no down time, driving their efficiency boost to a 50% gain.

Seamless Integration and Full Scalability

“It only took one day to install and commission the new Matthews Marking Systems’ solution,” says Espinosa. “And we didn’t have to change a thing on our side.” Designed to integrate easily with existing or new production lines, the V-Series DOD inkjet printer with MPERIA controller is a complete solution that can function in a stand-alone or networked environment. The modular nature of the system makes it easy to grow from one V-Series on a line to multiple V-Series printers on additional lines, all driven by a single controller.

Centralized Control and Usability

MPERIA gives Sierra Aluminum the capability to control marking and coding operations at any point on the production line from one central location. The single “one-touch” user interface controls all equipment—printers, barcode readers, vision systems, scales, and actuators—without the need for third-party software. MPERIA’s built-in message automation combined with the easy-to-use control interface provides labor savings over the previous CIJ solution by reducing equipment touches and the training requirement for line operators and maintenance personnel.

Clear, Crisp Marks

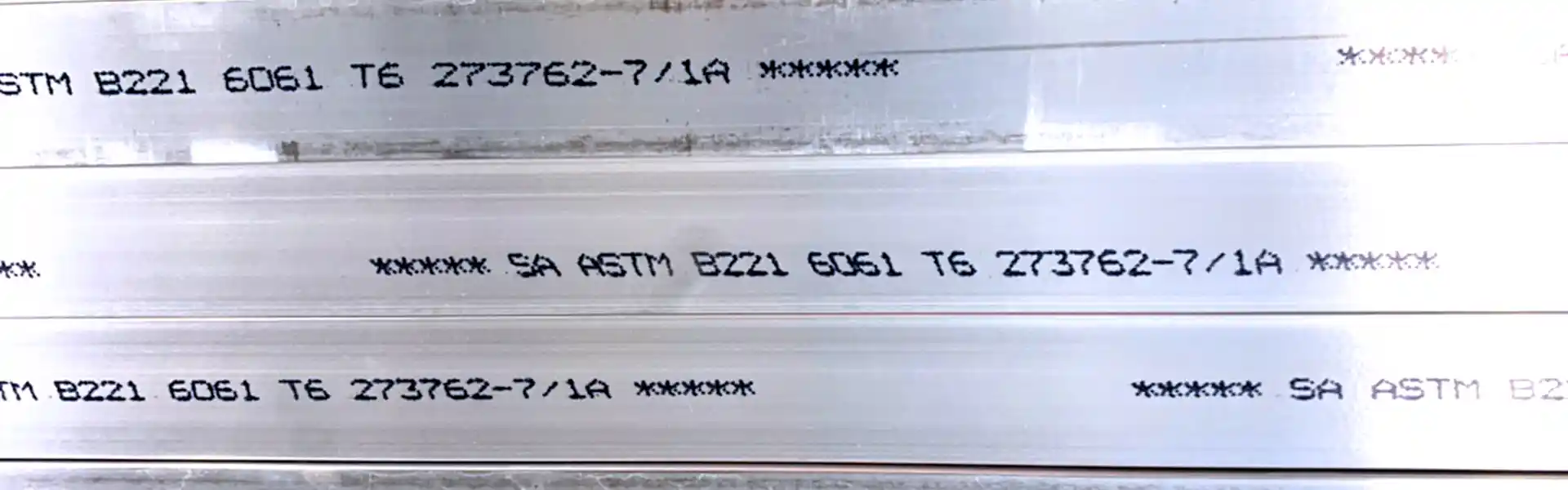

The V-Series DOD valve jet printheads produce incredible print quality on both porous and non-porous substrates including cardboard, wood, metal, rubber, and more. And they are able to achieve this high level of quality while also offering one of the fastest printing speeds in the industry at up to 780 feet per minute. The system is compatible with a wide variety of pigmented, dye-based, and fluorescent inks—including fast-dry versions—ensuring customers always have the exact ink needed for their mark.

The Results

“Matthews’ V-Series DOD inkjet printer has improved our efficiency by 50%,” says Espinosa. “In addition, the system is extremely robust and reliable, requires only minimal maintenance, and is much easier to operate. We finally feel confident that we can consistently deliver our customers’ orders on time.” In addition to these critical benefits, Sierra Aluminum also reduced their

consumable costs thanks to the V-Series more efficient ink usage and lower-cost inks. The company expects a full return on their investment within one year. By implementing Matthews Marking Systems’ V-Series DOD inkjet printer with MPERIA, Sierra Aluminum has successfully ensured the end-to-end efficacy of their operation and eliminated issues that were negatively affecting customer relations and brand reputation.