Alleviate one of your least favorite priorities: contemplating your product or package marking and coding. Our V-Series DOD inkjet printers give you unmatched reliability in the toughest environments. Small character to large character marking, with the ability to print very large marks with stitched printheads, the V-Series delivers incredible flexibility and unrivaled longevity, giving you full command of your production goals.

See in 2 minutes how to keep your production line marking and coding at peak productivity with the V-Series drop-on-demand inkjet printers.

Drop-on-Demand (DOD) inkjet printing gives you several operational advantages over many traditional mark and code printing, including the longest lasting printheads in the industry, ability to print both small and large characters at high speed, a much lower maintenance burden, faster installation, easier operation, and far greater system flexibility.

DOD valve-inkjet printing is fantastic for primary and secondary printing on a variety of both porous and non-porous substrates. Ideal applications include, but are not limited to, wood, building products, steel/metal, rubber, concrete, stone as well as corrugate packaging, bags, and cartons.

The ability to stitch multiple DOD printheads together and control them all from one central location gives you the flexibility and convenience you’ve been searching for on your production line.

Matthews Marking Systems’ V-Series DOD printers mark variable data, simple text, and medium resolution graphics at your line speed. Offering print sizes of ¼” to 5” with the capability of stitching for much larger marks; the V-Series easily tackles your small and large character alphanumeric text, batch, lot code, expiry date code, and graphics printing requirements. Unparalleled operation in challenging environments combined with outstanding flexibility and inks suited to your substrate provide an excellent solution for marking for most any application.

Achieving Production Goals

Cost savings.

Industry leading printhead life with an advanced nozzle design optimize ink usage lowering your operating cost. Bulk ink availability keeps your line running longer and a flushing valve system means easy maintenance.

Flexibility.

Three sizes of printheads with three nozzle sizes available for each gives you ultimate flexibility. Rotate your printhead to increase the resolution of your mark and choose the ink quantity needed to keep your line running.

Durability.

Over 9-billion firings before tuning and thriving in the toughest environments delivers incredibly reliability, meaning you get peace of mind year after year.

Automation.

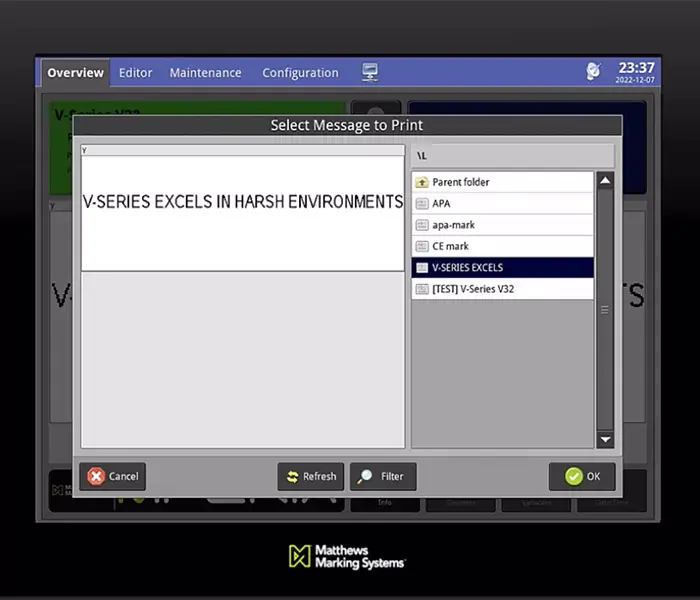

The V-Series is driven by our MPERIA®️ automated marking and coding platform that’s centralized and easily adaptable. From operating a single printer on a single production line to multiple marking systems across many lines, MPERIA is the industry’s only controller that can do it all.

See the Results

Read how Stone Truss increased efficiency and decreased costs with MPERIA and V-Series in the 15% Production Gain by Leading Truss Manufacturer case study.

Or how an aluminum manufacturer maintained customer satisfaction and achieved a 1-year ROI in the Metal Marking Gets 50% Efficiency Boost case study.

Interested in other applications where V-Series made its mark on a company’s bottom line?

Check out Marking and Coding Solutions for the Wood Industry and examples of Bag Marking.

We’re happy to provide a free site visit, product demo, and analysis of how we can help remove any headaches you have in your product or package marking and coding.