Mt. Olive Pickle, a premier producer of pickles and peppers, streamlines production with the help of the MPERIA® marking and coding system.

Don’t take our word for it, watch the full case study here.

Summary

Mt. Olive Pickle Company, Inc. (Mt. Olive Pickle) has been delighting customers for more than 95 years, annually producing millions of cases of pickles, peppers, and relish in their 300,000 sq ft facility. Ten production lines produce both six-pack cases and 12 pack cases of Mt. Olive Pickle branded products as well as third-party products.

The company found that dated marking equipment required substantial maintenance and did not provide the flexibility needed for the variety of tray packs Mt. Olive Pickle prints on. Additionally, the barcodes printed were inconsistent and not always readable, causing quality holds and potential rejection by their customers in distribution centers. Needing a new solution they shopped the market for a company with better technology and top-tier customer service.

“We looked at 3 or 4 other companies and other marking systems, but we chose Matthews for a variety of reasons. Number 1, we liked their technology. We liked the cartridge system, because every time we changed cartridges, we got a new printhead installed. We liked the options – they had bag systems or bulk systems. And the setup and customization we were able to do, Matthews worked with us throughout the whole project to a large testing timeframe, and we were able to do customizations that we needed to do. I thought the customer service was just excellent, so that’s a lot of the reasons we went with Matthews.” – Larry Beckman, VP of Manufacturing, Mt. Olive Pickle Company, Inc.

The Challenge

Mt. Olive Pickle was faced with illegible barcodes and unreliable marking equipment that was expensive to maintain. The old dot matrix style of printing experienced clogged ports that caused lines in their barcodes which made them unreadable. The legacy system was inflexible and forced Mt. Olive to deploy two different sets of printers to accommodate the variety of cases and tray packs they need to mark. And their customers wanted a better print setup that enabled barcodes to be scanned from a greater distance.

The Solution

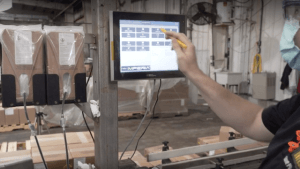

Matthews Marking Systems (Matthews) worked with Mt. Olive Pickle to install MPERIA L-Series thermal inkjet printers on ten of Mt. Olive Pickle’s manufacturing lines. The stitched L-Series L1 TIJ printers provide high-resolution 2-inch marking capability on both sides of their tray packs and cases. The solution includes the intuitive, easy-to-operate MPERIA controller for each of the production lines as well as the ABIS bulk ink supply system, giving Mt. Olive Pickle the ability to run nearly non-stop.

“So we worked with them to install VIAjet printer technology and that has proved to be very, very reliable, very clean and very good barcodes.” – Larry Beckman

Unlike the old print technology that required two different sets of printers, one set for six-pack cases and one for 12 pack cases, the MPERIA L-Series solution consolidated everything into one print area. This markedly improved efficiency while substantially reducing the maintenance burden.

Three Ways Mt. Olive Pickle Pepped Up Production:

1. Reduced scrap and re-work.

Crisp, clear, legible barcodes from the MPERIA L-Series gave Mt. Olive Pickle exactly what they and their customers in distribution needed. Cases and tray packs of pickles did not have to be re-worked because of poor print quality, giving Mt. Olive Pickle a productivity boost while reducing quality holds in distribution centers.

“We saw a reduction of 70-75% downtime related just to printer technology. And then we probably reduced our quality holds related to printing issues around 80% just by going to the new technology.” – Larry Beckman

2. Substantial maintenance savings.

Unlike the legacy marking system that required regular monitoring and maintenance, the MPERIA L-Series is incredibly easy to maintain. Swapping the print cartridge means a new printhead each time, removing one of the main pain points from the legacy system.

“With the previous printing system, we had one technician who spent probably 90% of his time doing nothing but maintaining the print systems. With the new Matthews system, we’re able to remove that person and distribute the maintenance and care to the operators on the line.” – Larry Beckman

3. Improved flexibility.

MPERIA L1 printheads are very compact and offer the additional benefit of being able to be stitched together in an array allowing larger prints or specific mark sizes. Mt. Olive Pickle eliminated a redundant set of printers and consolidated everything into one print area by deploying the L1s.

“Previously, we used to use two different sets of printers, we used one set of printers for six-pack cases and we used a second set of printers for 12 pack cases, and by going to this system, we consolidated everything into one print area.” – Larry Beckman

“Matthews offered us a system with a very consistent barcode…each cartridge prints a 1” row and we have it arrayed into a 2” stack setup so we can print a 2” high message on our trays.” – David Martin, Project Manager, Mt. Olive Pickle Company, Inc.

The Results

Mt. Olive Pickle was able to achieve a 30% reduction in the cost per mark on their cases and tray packs after installing the MPERIA L-Series solution. Additionally, they experienced a 70-75% reduction in downtime related to printer technology and a decrease of nearly 80% in quality holds related to marking problems from the legacy system.

“Through ink savings alone, we will have the entire cost as a capital project paid off in two-and-a-half years. And there’s an immense amount of maintenance savings and labor hours savings….I would absolutely recommend Matthews with the installation, the cost savings, the after-sales support, and the backup we get from their technical support services – have been amazing, it’s been great.” – David Martin

Quick responses and easy access to customer service and technical services ensured a positive outcome for Mt. Olive.

“Matthews has been very responsive to our needs, very prompt in providing assistance and help when we need them. I’ve been very pleased with the whole Matthews system. Both the customer service, reliability of the equipment, and the quality of the print that we get out of their system.” – Larry Beckman

“The customer service is fantastic. I can either call my local technician and get him on the phone before he hits another supplier, he’s local enough that sometimes he can come in that day. The technical services people, where I can just take a back-up of the unit and send it off to them, sometimes there a little bit of a lag, but I can still get an answer usually that day.” – David Martin

About Mt. Pickle Olive Company, Inc.:

Located at the Corner of Cucumber & Vine in Mount Olive, North Carolina, Mt. Olive Pickle Company, Inc. was originally founded for the purpose of brining cucumbers to be sold to other pickling firms, but quickly began processing and packing pickles itself, formulating their own recipes and methods of production. From a modest beginning in 1926, with only a 3,600 square foot building and $19,500 in capital, Mt. Olive has quickly grown to be one of the most loved pickle companies, manufacturing a best-selling brand of pickles, peppers, and relishes in the U.S for their millions of customers.

Get the Mount Olive Pickle Case Study

Tired of poor print quality leading to quality holds?

See how MPERIA can help improve traceability and reduce costly errors through centralization.