4Earth Farms, one of the largest organic produce suppliers in the U.S., plants seeds for the future with a Matthews’ turnkey automated labeling system.

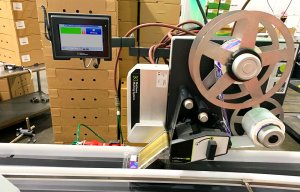

A-Series Labeller on 4EARTH Farms line.

Summary

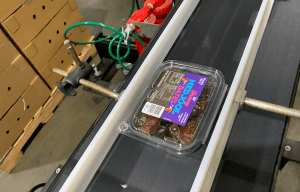

Serving some of the largest and best-known health food retailers and wholesalers worldwide, 4Earth Farms manages an enormous volume of organic, specialty, and conventional produce SKUs. Their 30,000-foot facility includes multiple production lines to serve a wide variety of product and packaging needs.

4Earth Farms’ operational productivity was severely impacted by the inefficiencies of their date labeling system requiring manual operation. To improve efficiency 4Earth Farms brought in Matthews Marking Systems (MMS) to build an engineered, turnkey, automated labeling solution. Matthews Marking Systems’ customized solution helped improve efficiency and reduce labor costs. The customized solution included the MPERIA® A-Series Print and Apply Automatic Labeling System with a T43 printer and conveyor. Once implemented, 4Earth Farms experienced increased production and reduced labor costs while delivering superior labeling consistency for well-known wholesale and retail clients.

The Challenge

4Earth Farms had recently updated its production line equipment with the goal of improving operational efficiency. Unfortunately, the dated labeling equipment was unable to keep pace with the new production equipment as operators had to manually operate the obsolete label applicators while hand-feeding products on the line. This process not only slowed production line efficiency but resulted in a substantial increase in labor costs; negatively impacting the bottom line.

“We needed an automated solution to help us increase line speed and efficiency, lower labor costs, and deliver a quality label that meets our customers’ high standards.” – Jose Molina, Maintenance Manager.

MMS Solution

Matthews Marking Systems engineered a customized, turnkey solution that combined the MPERIA® A-Series Print and Apply Automatic Labeling System with a conveyor in a complete unit that can move product throughout the 4Earth Farms facility for maximum convenience and efficiency. The solution includes the MPERIA® A-Series Print and Apply T43 printer, which uses thermal transfer technology, offering excellent barcode readability at 300 dpi and a print speed of up to 200 mm/s.

This new generation of print and apply label systems gives 4Earth Farms crucial precision and flexibility in a system that is easy to use, operationally efficient, and designed for safety. The compact unit enables easy installation, even in confined spaces, along with quick supply changeouts and simple message selections.

Consistent precision.

The automated system does not get tired or distracted, ensuring consistent and precise error-proof label placement. It also provides 4Earth Farms with highly flexible configurations and automated validation of code readability to ensure quality.

Safety assured.

With a minimum of moving parts and intelligent control to reduce trap points, the MPERIA A-Series reduces the risk of injury and allows for easier integration into production lines because it doesn’t require bulky cages or bolt-on protection measures. The MPERIA A-Series system recognizes and responds to obstructions without causing harm.

Easy installation and operation.

4Earth Farms can quickly move the system from station to station within their facility, providing coverage across multiple production areas thanks to the inherent simplicity and flexibility of the A-Series and customized solution by MMS. The MPERIA® controller’s intuitive touchscreen provides an operator-friendly user interface, while unrestricted access to the label path makes changing labels and ribbons quick and effortless for anyone.

Simple scalability.

The MPERIA controller enables 4Earth Farms to easily scale from a single A-Series printer to additional printers across multiple lines. Centralized message creation and code automation through a single, intuitive interface seamlessly integrates label verification and validation without expensive middleware.

The Results

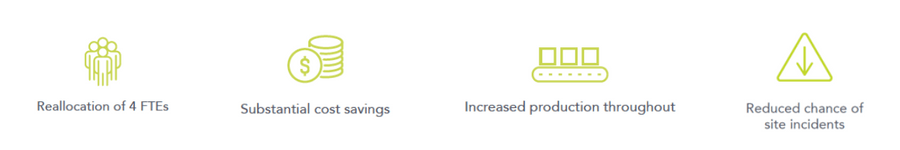

4Earth Farms achieved continuous production flow and significant labor savings with the MPERIA® A-Series Print and Apply Automatic Labeling System. Increased line speeds, efficiency, and better utilization of personnel — with four operators shifting to other roles in the organization — led to a positive impact on their bottom line.

“We are so pleased with the initial MPERIA Print and Apply Automatic Labeling System, It has saved us time and money, and helped make our operation much more efficient…we are already planning to implement seven additional stationary labelers for box coding, and we look forward to seeing similarly positive results.“ -Jose Molina, Maintenance Manager.

About 4Earth Farms:

Founded in 1993, 4Earth Farms is one of the nation’s largest vertically integrated conventional, organic, and specialty grower-packer-shippers. Located in Los Angeles, they supply a wide range of clients (wholesale and private label) with more than 150 year-round organic SKUs, 250 specialty products, and conventional fruits and vegetables. Their “farm-to-fork” approach and direct relationships with growers in Chile, Taiwan, Thailand, China, and South Africa help them deliver on their commitment to environmental stewardship, corporate social responsibility, and the 21st-century principles: People. Produce. Planet.

Get the 4Earth Farms Case Study

Interested in other applications where the MERPIA A-Series made a difference?

See how a large citrus grower planted seeds for future growth with automation and used the MPERIA A-Series to make its mark on the company’s bottom line.