Prevent costly errors by streamlining your marking and coding with centralized control.

A customer recently told us that this was the first year they were required to mark every clamshell for a produce client they pack for. For years, we’ve heard that traceability was moving up the supply chain – now it’s here.

Marking a date, lot, or batch code on a package has become standard operating procedure (SOP). Individually managing this new SOP on multiple production lines can increase the risk of human error. Managing your operations from a central location has numerous benefits, including helping mitigate this risk. Significant marking/coding/labeling errors can lead to regulatory penalties, fines for non-compliance, inaccurate labeling of the whole batch, product recalls, incorrect product getting into the supply chain, or product unavailability during the restocking period. All of these are damaging to your production and brand reputation.

“MPERIA platform is so easy to use, compared to having to operate through a small touchscreen on a localized unit, I can sit in my office with the AC on, and custom modify labels and make changes on the fly.” – Tony Atchley, Ventura Pacific, Plant Manager – Consumable Cost Cut by 80% for Produce Packer Case Study

Lower risk.

MPERIA® can help eliminate these costly errors by centralizing message creation and print controllers into one interface. Whether it’s a scannable barcode, a 2D code (DataMatrix, QR, etc.), or a human-readable date, the MPERIA platform can manage and print messages to your whole line from one controller – lowering risk, ensuring compliance, reducing operating costs, and reducing the impact on your IT team with less hardware and software maintenance activities.

Keep it simple.

Data is key in the new world of tracking and tracing products through the supply chain. Integrating back-end data systems and enterprise applications is essential to ensure accurate data is being printed on the products.

MPERIA simplifies integration and data management. It can pull data from multiple systems that manage data (ERP, MES, WMS) and eliminate the need for managing a new and separate database or the complex process of ensuring synchronization. It also lowers risk by reducing points of failure in your entire operating equipment system. Centralization brings simplicity.

Fewer controllers = fewer message selection activities = fewer chances of incorrect message selection. Every input activity is an opportunity for error, so reducing human activities improves quality.

Ensure compliance.

You can create a variable in your central location and use it on one or all printers to develop consistency, verify correct input, and validate the correctness of data thanks to MPERIA’s simple input validation feature.

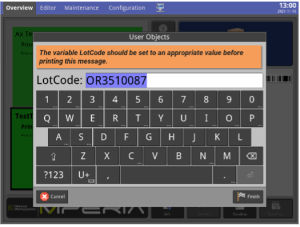

Simplify traceability compliance by creating a lot code for your facility. For example, your format could be two letters indicating the state followed by nine numbers indicating the plant and lot. Use the input validation feature in variable creation to ensure your whole plant complies with the format.

Using that as an example, here’s how you would implement it in the MPERIA platform:

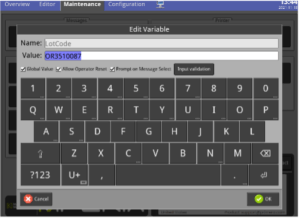

Create a variable “Lot Code” and make it global by checking the Global Value box. Put a check in the “Prompt on Message Select” to ensure the operator enters the current lot code before printing.

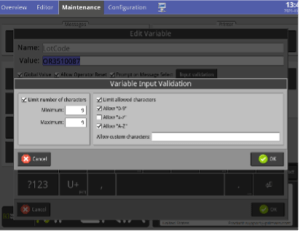

Select the Input Validation button to add constraints to the Variable.

In this example, the lot code is always nine characters, using capital letters and digits 0-9. No custom characters will be allowed.

Use the variable to build your barcode or human-readable code. Simply insert the variable in a text field on your message or when creating a barcode using the tool in the Message Editor.

Additionally, MPERIA can connect to vision systems to verify that the code can be read after printing. Finding non-readable codes before release into the supply chain reduces the chance that products will experience a fine or a problem in transportation or sale.

Reduce operating costs.

The MPERIA platform combines the essential software for print control, line control, message creation, secure file transfer, and cost estimation and planning into a straightforward software interface. Combining all into one allows for simple training of full-time and seasonal workers. By controlling multiple printers from one location, you eliminate unnecessary, redundant actions across product lines, opening up your team to utilize resources across the facility better.

By combining the message creation with the cost estimator, you can also create more efficient messages right on your controller. Select the Message Info button at the bottom of the Message Editor, enter your ink type and ink cost. MPERIA will calculate the approximate mark cost allowing you to adjust size, font, and text to meet message/mark cost goals.

Centralizing your print operations with MPERIA can even result in a higher Overall Equipment Effectiveness (OEE) due to higher quality and the ability to centrally view availability and performance. Catching quality issues with a vision system before any re-work is needed will improve your quality score.

Fewer devices to maintain.

According to a VDC and Loftware survey on enterprise labeling applications, “while these design applications are leveraged as a single source of truth, their capabilities are typically inflexible, require significant IT oversight, and are not designed to accommodate constant labeling changes.” MPERIA was designed to address these issues. The need for constant message/label changes was specifically considered with the production line operator in mind, ensuring quick and easy changes.

MPERIA controllers also have built-in operating systems that don’t need to be maintained by IT and enables multiple printers to be run off of a single controller reducing the hardware required. With fewer controllers, there’s less time dedicated to software maintenance and upgrading the controllers. And, by using the VNC feature of the MPERIA controllers, the IT Manager can upgrade all software from the comfort of their office. Reducing the hardware and software footprint to maintain is excellent for your IT team.

Centralization benefits your whole team.

| Who | Key Benefit |

| Production Line Operator | Fast message switching |

| IT Manager | Fewer controllers to maintain and only one software package to maintain |

| Message Designer | Easy to create new messages and modify current messages quickly |

| Production Line Worker | Simple training of seasonal workers |

| Line Production Supervisor | Integrated cost estimation and message planning |

| Custodial Staff | Fewer parts to clean |

| Quality Assurance Inspector | Assurance of input format for message creation |

| Pack Line Manager | Improvement of OEE |

Centralization with the MPERIA® platform means:

- One platform to learn.

- One platform to operate.

- One platform to maintain.

- One platform to rule them all.

See how a marking and coding controller can lead to measurable results on your whole production line, from product to pallet.

Find the MPERIA controller best suited for your environment.

Check out all the different MPERIA controller options available.